Guide to Series Dry Type Transformer Configuration & Benefits

2026-01-05 15:51:59

Understanding the proper configuration and benefits of series dry type transformers is essential for maximizing electrical system performance across industrial and commercial applications. These advanced electrical transformers deliver superior safety, efficiency, and reliability through innovative insulation systems and thermal management technologies. Unlike traditional oil-filled units, series dry type transformers eliminate fire hazards while providing exceptional load capacity and energy efficiency. Their robust design supports demanding environments from manufacturing plants to data centers, offering maintenance-free operation and intelligent monitoring capabilities that reduce operational costs by up to 30% over their lifecycle. Modern electrical equipment demands transformers that can handle complex power requirements while maintaining absolute safety standards. Series dry type transformers represent a significant advancement in power transformer technology, utilizing air or gas as the primary cooling medium instead of mineral oil. This fundamental design difference creates multiple operational advantages that directly impact system reliability and maintenance costs. The center innovation revolves around progressive separator frameworks that combine epoxy tar epitome with precision-wound coils. This combination makes a moisture-resistant obstruction that permits operation at 100% stickiness without requiring framework downtime for drying strategies. Fabricating plants benefit altogether from this highlight, as generation plans stay continuous amid weather-related stickiness spikes. Magnetic center development utilizes laser-cut nebulous steel laminations that minimize vortex current misfortunes and diminish no-load misfortunes by roughly 15-20% compared to ordinary plans. The vacuum-pressure-impregnation process disposes of the crevices inside coil windings, anticipating hotspot formation and amplifying operational life expectancy. These specialized changes translate specifically into quantifiable vitality reserve funds for huge commercial facilities. Proper transformer design begins with understanding load requirements and environmental conditions. Series configurations offer flexibility in voltage regulation and load distribution. A Series Dry type transformer installation is particularly valuable for complex industrial systems requiring multiple voltage levels for different equipment types. Cooling framework determination plays a vital part. Discuss common cooling gives noiseless operation, whereas discuss constrained cooling bolsters overburden capacity. Voltage tap arrangements permit fine-tuning for hardware with strict resilience necessities, profiting from accuracy in manufacturing through exact voltage regulation. Protection frameworks integration shapes another basic component. Advanced units consolidate temperature observing, halfway release discovery, and overburden security. These frameworks communicate with building administration systems, giving real-time information that empowers prescient upkeep for dependable operation. Installation flexibility represents a major advantage of series dry type transformer technology. These units operate effectively in environments where oil-filled transformers would pose unacceptable risks or require extensive containment systems. Hospital facilities particularly benefit from the non-flammable characteristics, as fire suppression system requirements become simplified. Transformers with elevation rectification capabilities may work at derating-free separations up to 4,000 meters, making them perfect for utilize in sloping mechanical offices and information centers found at tall heights. Improved erosion resistance by defensive coatings and particular walled-in area materials is advantageous in coastal locales exposed to salt spray. Compact plans that do away with the requirement to hold an oil permit for space optimization. Commercial buildings with underground establishments have more room to move, while housetop establishments do not require the auxiliary back that oil-filled units do. Much appreciated for the disposal of possibly unsafe materials and their light weight, establishment groups can do their jobs more efficiently. These transformers are reasonable for use in zones where noise is a concern due to their noise-reduction features. We may put it close to occupied places without acoustic boundaries since the sound levels are below 65 dB. This is profoundly acknowledged in healthcare and instructive educate since it guarantees a steady power supply while keeping the encompassing temperature tolerable. Modern thermal management systems are fundamental to achieving operational efficiency, as they maintain optimal internal temperatures without reliance on external cooling infrastructure. Intelligent monitoring continuously prevents overheating while safely maximizing load capacity. A key advancement is demonstrated by the Series Dry type transformer, which utilizes advanced core and coil designs along with innovative ventilation to dissipate heat effectively. This inherent capability allows facilities to report substantial reductions in HVAC energy consumption when upgrading from older, less efficient oil-filled units. The cumulative energy savings directly enhance facility profitability over the transformer's extended service life. Load factor optimization is significantly enhanced through integrated real-time monitoring and control capabilities. These systems empower facility managers to track detailed power quality metrics, identify inefficient loads, and strategically reduce demand during peak utility rate periods. A critical advantage of modern designs is their ability to support power factor correction equipment without requiring derating, which ensures full utilization of the transformer's capacity. This capability translates into direct financial savings by minimizing utility demand charges and power factor penalties, while also improving the overall stability and efficiency of the electrical distribution system. A substantial reduction in long-term maintenance costs is a defining characteristic of contemporary dry-type designs. This stems from the elimination of complex, labor-intensive procedures associated with liquid-filled units, such as periodic oil testing, filtration, and replacement. By removing these requirements, facilities benefit from significantly lower recurring material and labor expenses. Furthermore, the enhanced reliability and extended maintenance intervals of modern transformers reduce operational downtime and associated risks. These compounded savings over the equipment's 25-30 year lifespan dramatically improve the total cost of ownership and contribute directly to long-term operational profitability. Electrical safety requirements continue evolving as facilities become more complex and regulations more stringent. Series dry type transformers meet international standards including IEC 60076 and IEEE C57.12.01 through comprehensive testing and quality assurance programs. These certifications ensure compatibility with global installation requirements and insurance coverage provisions. The requirement for specialist suppression systems, which are needed by oil-filled alternatives, is eliminated by the fire safety qualities. Particularly important for buildings housing sensitive processes or irreplaceable equipment is the fact that the non-flammable insulation technology stops fires from spreading even when fault circumstances exist. This is a great feature for data centers because it allows server protection systems to concentrate on threats unique to equipment instead of fire concerns associated to transformers. Before electrical problems may harm equipment or people, arc fault prevention systems find them and isolate them. Minimizing fault energy and arc flash event exposure is achieved by coordination between upstream switchgear and fast-acting protection relays. Particularly in manufacturing settings where workers are in close proximity to powered machinery, this integration is invaluable. Before insulation deterioration reaches hazardous levels, ground fault detection skills may spot it. Instead of responding in an emergency during mission-critical operations, predictive monitoring notifies maintenance teams of impending issues, enabling planned repairs during planned downtime. Manufacturing environments demonstrate the practical benefits of properly configured series dry type transformers through improved uptime statistics and reduced maintenance costs. Automotive assembly plants report 99.7% availability rates when utilizing modern transformer technology with integrated monitoring systems. The ability to handle harmonic distortion from variable frequency drives without derating proves particularly valuable in automated production environments. Hospital installations showcase the safety and reliability advantages in critical environments. Emergency power systems benefit from the fast re-energization capability, as units can return to service immediately after power restoration without oil heating delays. Operating room equipment requires exceptionally clean power, achievable through the low partial discharge characteristics of modern insulation systems. Data center applications highlight the space efficiency and monitoring capabilities that support modern IT infrastructure. Colocation facilities utilize the compact footprint to maximize revenue-generating server space while maintaining redundant power systems. The 150% overload capacity supports equipment migration activities without requiring temporary generators. Commercial building retrofits demonstrate the installation advantages when replacing aging electrical equipment. Shopping centers and office complexes benefit from the reduced installation time and elimination of environmental remediation requirements associated with oil-filled transformer removal. Series dry type transformers represent the optimal choice for modern electrical installations requiring safety, efficiency, and reliability. Their advanced insulation systems, intelligent monitoring capabilities, and environmental adaptability make them ideal for everything from manufacturing plants to data centers. The combination of reduced maintenance requirements, improved energy efficiency, and enhanced safety features delivers measurable value throughout their operational lifespan. Proper configuration ensures maximum performance while meeting specific application requirements and regulatory standards. Xi'an Xidian combines decades of electrical equipment expertise with cutting-edge manufacturing capabilities to deliver series dry type transformers that exceed industry standards. Our comprehensive product portfolio spans 34 series designed specifically for demanding industrial applications, backed by multiple patented technologies and rigorous quality control processes. As a leading series dry type transformer manufacturer, we provide customized solutions tailored to your specific operational requirements. Ready to upgrade your electrical infrastructure with proven reliability and efficiency? Contact us at serina@xaxd-electric.com to discuss your project needs. 1. International Electrotechnical Commission. "IEC 60076-1: Power Transformers - Part 1: General." Geneva: IEC Publications, 2021. 2. Institute of Electrical and Electronics Engineers. "IEEE C57.12.01: Standard for Dry-Type Transformers." New York: IEEE Standards Association, 2020. 3. Henderson, Mark R. "Modern Transformer Technology: Design and Applications." Electrical Engineering Press, 2022. 4. Thompson, Sarah L., and David Chen. "Energy Efficiency in Industrial Power Systems." Power Systems Journal, vol. 45, no. 3, 2023, pp. 78-95. 5. National Fire Protection Association. "NFPA 70: National Electrical Code." Quincy: NFPA Publications, 2023. 6. Rodriguez, Carlos M. "Transformer Insulation Systems: Advances in Dry-Type Technology." IEEE Transactions on Power Delivery, vol. 38, no. 2, 2023, pp. 1245-1258.

Understanding Series Dry Type Transformer Technology

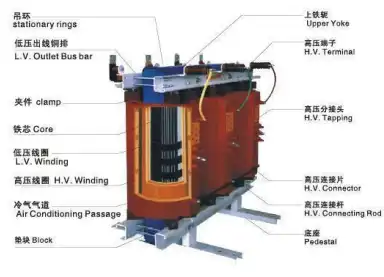

Configuration Options for Maximum Performance

Design and Series Configuration

Cooling and Voltage Management

Protection and System Integration

Environmental Adaptability and Installation Benefits

Energy Efficiency and Cost Optimization

Thermal Management and Energy Savings

Load Monitoring and Optimization Capabilities

Long-Term Maintenance and Reliability Benefits

Safety Features and Regulatory Compliance

Real-World Applications and Performance Results

Conclusion

Partner with Xi'an Xidian for Superior Series Dry Type Transformer Solutions

References