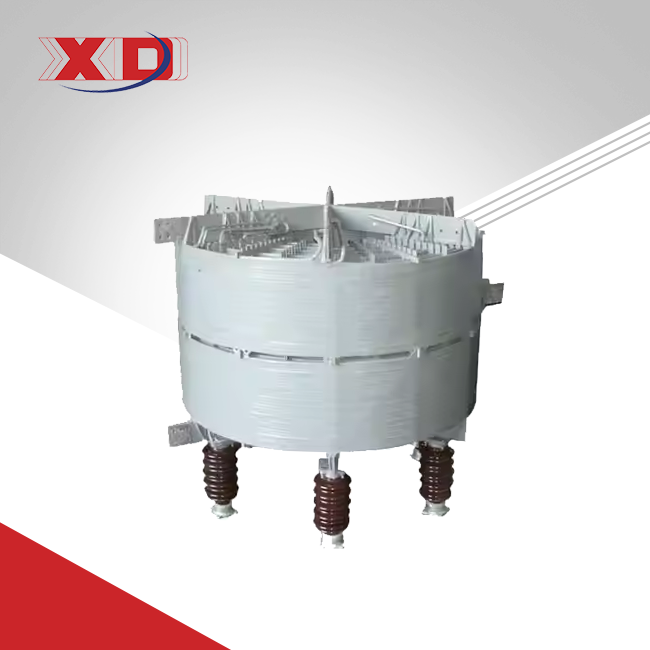

50KVAR Self-healing Capacitor for PFC(Power factor correction)-square BKMJ

10KV High voltage Shunt High-Voltage Capacitors

2.Rated Capacity:1-100Mvar(per bank)

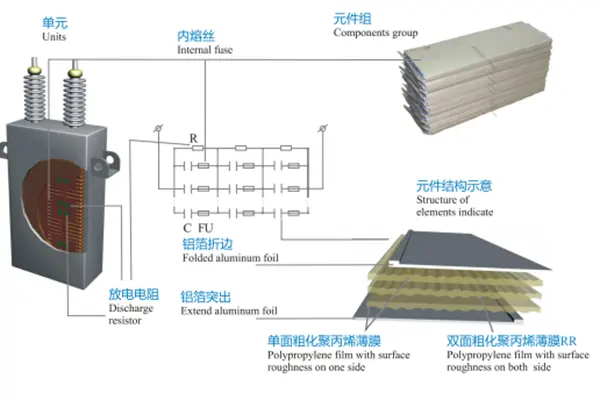

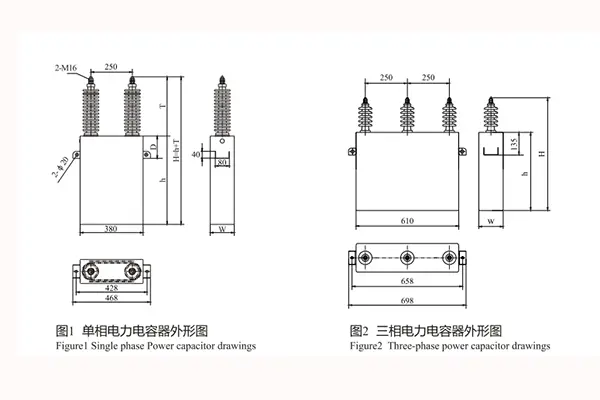

3.The capacitor is mainly consisted of container and device body.

4.The core is consisted of severalelements and insulation parts. The element is rolled, pressed andmade of two aluminum foilsand somepiece of thin dielectric polypropylene films sandwiched betweenthe two aluminum foils. In order to reach the differentdemand of voltage and capacity, the elements in core is connected by someseriesand parallelmethod. The technology of aluminum foiledge folding and protruding weldingare used to reduce the loss and increase the performance of partial discharging.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1.10KV High voltage Shunt High-Voltage Capacitors: Powering Efficient Grids & Industries

When your operations demand reliable energy efficiency and grid stability, 10KV High voltage Shunt High-Voltage Capacitors deliver unmatched performance. Designed for heavy industries, renewable energy systems, and urban infrastructure, these capacitors optimize power factor correction, reduce energy loss, and suppress harmonics—ensuring your systems meet stringent compliance standards while lowering operational costs.

|

|

|

|

|

|

2.Technical Specifications

- Rated Voltage: 6kV, 10kV, 35kV

- Capacity Range: 1–100Mvar (per bank)

- Construction:

- Container: Durable, corrosion-resistant casing.

- Core: Aluminum foils layered with polypropylene films for high dielectric strength.

- Connections: Series/parallel configurations to match voltage and capacity needs.

- Certifications: ISO 9001, IEC 60871-1, UL 810.

| Type | Rated Voltage | Rated Output | W (mm) | h (mm) | H (mm) | D (mm) |

| BAM11/ √3-200-1W | 11/ √3 | 200 | 145 | 530 | 835 | 135 |

| BAM12/ √3-200-1W | 12/ √3 | 200 | 145 | 520 | 825 | 135 |

| BAM10.5/√3-334-1W | 10.5/ √3 | 334 | 185 | 620 | 925 | 135 |

| BAM11/2-334-1W | 11/ 2 | 334 | 185 | 640 | 945 | 135 |

| BAM12/2-344-1W | 12/2 | 334 | 185 | 640 | 945 | 135 |

| BAM11/ √3-334-1W | 11/ √3 | 334 | 185 | 640 | 945 | 135 |

| BAM12/√3-344-1W | 12/ √3 | 334 | 185 | 620 | 925 | 135 |

| BAM11-334-1W | 11 | 334 | 185 | 760 | 1065 | 275 |

| BAM12-344-1W | 12 | 334 | 185 | 760 | 1065 | 275 |

| BAM11/√3-417-1W | 11/ √3 | 417 | 185 | 770 | 1075 | 275 |

| BAM12/√3-417-1W | 12/ √3 | 417 | 185 | 770 | 1075 | 275 |

| BAM11/2-417-1W | 11/2 | 417 | 185 | 760 | 1065 | 275 |

| BAM12/2-417-1W | 12/2 | 417 | 185 | 760 | 1065 | 275 |

| BAM11/2-500-1W | 11/2 | 500 | 210 | 820 | 1125 | 300 |

| BAM12/2-500-1W | 12/2 | 500 | 210 | 820 | 1125 | 300 |

| BAM21/2-500-1W | 21/21 | 500 | 210 | 840 | 1145 | 300 |

| BAM23/2-500-1W | 23/2 | 500 | 210 | 820 | 1125 | 300 |

3.Key Features & Advantages

1. Precision Harmonic Suppression

Combat 3rd, 5th, and 7th harmonics effectively with integrated reactors (5%–12% options), reducing grid interference and equipment overheating risks.

2. Enhanced Grid Stability

Improve power factor to 0.95+ and minimize reactive power penalties, even in dynamic environments like steel mills or solar farms.

3. Robust Safety Mechanisms

- Discharge Coils: Safely discharge residual voltage within 5 minutes.

- Zinc Oxide Arresters: Prevent overvoltage surges during switching.

- HV Fuses: Isolate faults to avoid cascading failures.

4. Customizable Designs

Tailor capacitor banks with IoT-enabled controllers, explosion-proof enclosures, or desert-proof IP55 casings for harsh environments.

4.Real-World Applications

Be used in a wide range of industries.

Industrial Plants

Eliminate power factor penalties in CNC machines and assembly lines while handling surge currents up to 100x rated capacity.

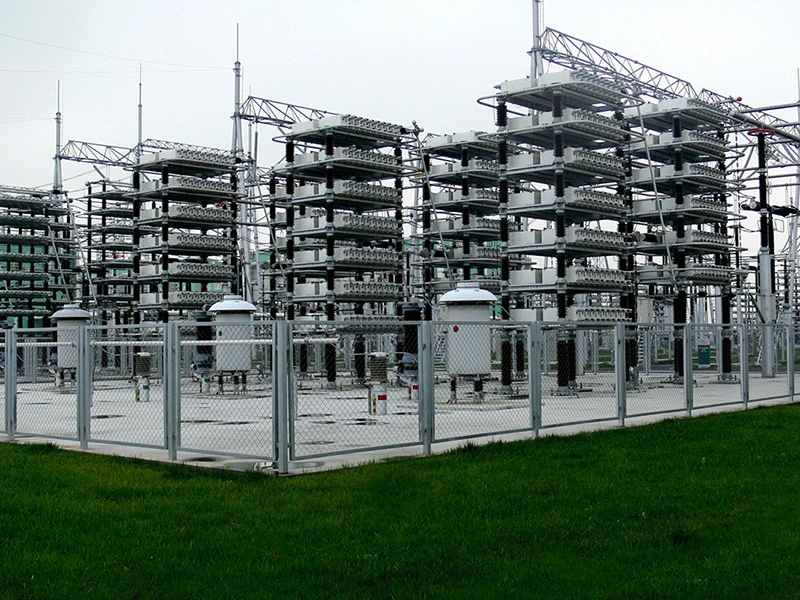

Substation

Stabilizes substation voltage against harmonics and intermittent generation from renewable inverters.

Commercial Buildings

Retrofit aging systems in hospitals or malls with silent (<45dB), flame-retardant capacitors that meet NFPA 70 fire codes.

5.How It Works: Design & Performance

The capacitor’s core 10KV High Voltage Shunt High-Voltage Capacitors uses folded aluminum foils and polypropylene films to minimize losses and partial discharge. Elements are connected in series/parallel to achieve target voltage and capacity, while advanced welding techniques enhance durability. Paired with vacuum circuit breakers and reactive power controllers, these capacitors automatically adjust to load changes, maintaining optimal grid performance.

6.Manufacturing Excellence

- Quality Assurance: Every unit undergoes partial discharge tests (<10pC), thermal cycling (-40°C to +55°C), and impulse voltage checks.

- Eco-Friendly Production: Solvent-free materials and energy-efficient processes align with global sustainability goals.

7.Why Choose Us?

- 30+ Years Expertise: Trusted by top-tier clients in 50+ countries.

- End-to-End Support: From design to installation and 24/7 maintenance.

- Proven Innovation: 15+ patents in high-voltage capacitor technology.

8.FAQ

Q: How long do these capacitors last?

A: With proper maintenance, expect 100,000+ operational hours—15+ years in typical industrial settings.

Q: Can they handle high inrush currents?

A: Yes! Our capacitors integrate pre-insertion resistors and reactors to limit inrush currents to safe levels.

Q: Are they compatible with smart grid systems?

A: Absolutely. We offer SCADA-ready models with real-time monitoring via IoT controllers.

9.Contact Us

Email xaxd_electric@163.com for a free consultation. Share your voltage, capacity, and environmental needs—we’ll craft a solution that boosts efficiency and cuts costs.

Your Grid Deserves the Best. Partner with Experts Who Deliver 10KV High Voltage Shunt High-Voltage Capacitors.

10.Factory Show

11.Equipment Display

12.Application Cases

State Grid systems, power engineering, steel and metallurgy, petrochemicals, rail transportation, energy and water conservancy, construction, environmental protection, and renewable energy sectors

13.Team and Exhibition

Send Inquiry

-square BKMJ_1758505876091.webp)