How Current Transformers Improve Power System Monitoring?

2026-02-10 16:04:04

Current transformers fundamentally revolutionize power system monitoring by providing accurate, real-time current measurements while ensuring operator safety and equipment protection. These electromagnetic devices step down high currents to manageable levels, enabling precise monitoring of electrical parameters across complex industrial infrastructures. Through electromagnetic induction principles, a current transformer creates isolated secondary circuits that deliver scaled current readings to meters, relays, and monitoring systems without direct electrical connection to dangerous primary circuits.

|

|

Understanding Current Transformers and Their Working Principles

Current transformers function by electromagnetic induction, turning large primary currents into proportionate secondary currents at safe, quantifiable levels. The essential architecture comprises of one primary winding linked in combination with the electronic device under observation, a supplementary winding that generates the scaled output, or a magnetic core that permits energy transfer amongst windings.

Core Components and Electromagnetic Principles

The core of magnetic field serves as the basis for current transformation, often built from silicon steel veneers that reduce energy losses. Primary current causes a magnetic flux inside the center of the capacitor, which induces a comparable current in the other winding corresponding to the degrees ratio. This electromagnetic connection provides precise current reproduction while preserving electrical isolation between higher-voltage primary systems and low-voltage monitoring devices.

Types of Current Transformers for Different Applications

Industrial applications utilize various CT configurations based on installation requirements and performance specifications:

- Solid core transformers provide maximum accuracy and stability for permanent installations in substations and switchgear

- Split core designs enable retrofit installations without circuit interruption, ideal for existing industrial facilities

- Low burden units minimize power consumption while maintaining accuracy, supporting modern digital monitoring systems

- Standard burden transformers accommodate traditional electromechanical meters and protective relays

Each type addresses specific operational challenges, allowing procurement professionals to match transformer characteristics with system requirements and installation constraints.

Enhancing Power System Monitoring Through Current Transformers

Current transformers enable comprehensive power system monitoring by delivering accurate current measurements for energy management, protection schemes, and operational analysis. These devices provide the foundation for load monitoring, fault detection, and system optimization across industrial facilities.

Real-Time Monitoring and Load Management

Modern power systems necessitate continual monitoring to ensure operating efficiency and minimize expensive downtime. Current transformers offer real-time current information in order supervisory control systems, allowing operators to watch load trends, discover inefficiencies, and optimise energy use. This capacity proved especially helpful in industrial facilities and data parks where the quality of power directly effects output and equipment performance.

System Protection and Fault Detection

Protection systems depend on electricity transformers to detect unusual conditions during operation and execute protective measures. When fault currents surpass predefined levels, CTs give the appropriate signals for interrupters and relays with protection to separate afflicted equipment. This quick reaction capacity protects important industrial equipment and ensures uninterrupted service during electrical disruptions.

Distinguishing Current Transformers from Potential Transformers

Potential transformers assess voltage characteristics, while current transformers track electrical current. These complimentary devices operate together to offer comprehensive power system monitoring, allowing precise computation of power consumption, factor of return, and energy quality indicators. Understanding this difference enables facility operators build complete monitoring techniques that handle both voltage as well as current measurement needs.

Choosing the Right Current Transformer for Industrial Power Systems

Selecting adequate current transformers needs careful examination of accuracy necessities, burden parameters, ratio calculations, plus environmental circumstances. The selection effects measurement accuracy, installation versatility, and long-term system dependability.

Accuracy Classes and Burden Considerations

Current generator accuracy classes establish measurement precision under defined operating circumstances. Class 0.2 units deliver high accuracy suited for revenue metering use, while Class 1.01 transformers give acceptable precision for ordinary monitoring purposes. Burden standards govern the maximum load that may be connected to main circuits with no loss in accuracy, making appropriate burden calculation vital for preserving measurement integrity.

Ratio Selection and Calculation Methods

Current distributor ratios must match main circuit currents to downstream circuit needs. Standard ratios vary from 5:5 amplifiers for low- current situations to four thousand amperes for massive industrial circuits. Proper ratio selection enables excellent accuracy while avoiding saturation at normal and fault situations. The computation is figuring out the highest anticipated primary current and choosing a ratio that keeps the operation inside the CT characteristic curve's linear range.

Environmental Resilience and Installation Flexibility

Industrial settings bring distinct issues including temperature fluctuations, moisture exposure, plus mechanical vibration. Current transformers must endure these environments while retaining accuracy throughout their operating lives. While solid cores provide better accuracy for new building projects, split core designs offers installation benefits in retrofit situations.

Procurement Insights for Current Transformers in Global B2B Markets

Effective procurement techniques concentrate on discovering dependable suppliers, analyzing product requirements, and getting competitive price for quality transformers for current. Global marketplaces provide multiple possibilities, requiring rigorous supplier assessment and technological examination.

Supplier Evaluation and Quality Assessment

Reputable manufacturers maintain thorough quality control systems and give full technical specifications for their current generator products. Key assessment factors include ISO certificates, conformity with worldwide regulations such as Cc 61869, and established performance histories in comparable applications. Assistance capabilities and warranty clauses may impact supplier selection choices.

Pricing Strategies and Supply Chain Management

Bulk purchasing agreements often provide cost advantages for large-scale projects, while custom manufacturing options address unique application requirements. Current transformers are a key component where these considerations apply, as their lead times vary significantly between standard and specialized units, making early procurement planning essential for project success. Establishing relationships with multiple suppliers helps ensure continuity of supply and competitive pricing throughout project lifecycles.

Technical Specification Verification

Important performance metrics, such as accuracy class, workload rating, heat rating, and insulation levels, are revealed via datasheet examination. Performance testing findings verify manufacturer claims and show adherence to relevant requirements. Third-party testing certifications give more trust in product quality and its consistency across manufacturing batches.

Installation, Testing, and Maintenance Best Practices

Proper installation, set up, and service processes provide optimum current transformer function throughout the equipment lifespan. These procedures preserve measurement precision and system dependability while safeguarding worker safety.

Installation Guidelines and Safety Protocols

Current transformer installation needs adherence for the producer specifications in addition to safety regulations. Primary connections must handle rated current without overloading, while secondary circuits need suitable grounding and load connections. Safety guidelines demand that extra circuits never run in open-circuit circumstances, which may create harmful voltages and injure the transformer.

Field Testing and Commissioning Procedures

Commissioning tests evaluate transformer current performance before energization. Ratio testing validates optimal turns ratio, meanwhile polarity tests assure accurate phase connections. Insulation resistance tests establish electrical integrity between main, secondary, plus ground circuits. These tests give baseline data on performance for future evaluation and repair actions.

Preventive Maintenance and Lifecycle Management

Regular maintenance programs extend current transformer lifespan while maintaining accuracy and reliability. Visual inspections identify physical damage or deterioration, while electrical testing monitors performance changes over time. Thermal imaging detects connection problems before they cause failures, supporting predictive maintenance strategies that minimize unplanned outages.

Company Introduction & Our Current Transformer Solutions

Xi'an Xidian Medium & Low Voltage Electric Co., Ltd. represents one of China's largest manufacturing bases for medium and low-voltage electrical equipment, providing advanced current transformer solutions for global industrial applications. Our comprehensive product portfolio encompasses multiple current transformer series designed to meet diverse monitoring and protection requirements across various industries.

Advanced Manufacturing Capabilities and Quality Systems

Our current transformer manufacturing employs state-of-the-art processes including vacuum casting technology that eliminates air pockets for superior insulation performance. Precision winding machinery ensures consistent turns ratios and optimal magnetic coupling between primary and secondary circuits. Rigorous testing protocols including partial discharge testing, thermal cycling, and seismic validation demonstrate our commitment to product reliability and longevity.

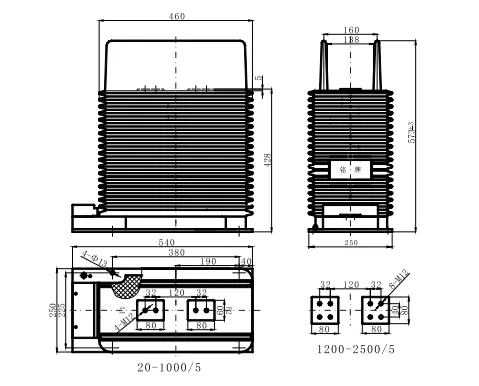

Product Range and Customization Options

Our voltage converter solutions have all-weather dependability with completely enclosed, epoxy-sealed designs and resist moisture, sunlight exposure, and environmental contaminants. Smart grid compatibility provides minimal error rates of ±0.2% while enabling huge capacity needs for real-time monitoring apps. Because of these features, our products are perfect for high-altitude installations, coastal areas, and tough industrial settings where dependability cannot be compromised.

Our current transformers are more cost-effective in the long run since they need less maintenance and have operating lifespans longer than 20 years. This longevity considerably minimizes downtime and replacement expenses while assuring constant performance across the equipment lifespan.

Global Reach and Application Success

Our transformer for current solutions serve numerous applications such utility grids, industrial facilities, renewable energy grids, and rail networks. Our capacity to handle complicated monitoring needs spanning numerous sectors is shown by our success in State Grid systems, electric power projects, steel among metallurgy facilities, petroleum plants, and green energy installations.

Conclusion

Current transformers serve as the backbone of modern power system monitoring, enabling accurate measurement, protection, and control across industrial facilities. Their ability to provide safe, isolated current measurements while maintaining high accuracy makes them indispensable for operational efficiency and equipment protection. The selection process requires careful consideration of accuracy requirements, environmental conditions, and application-specific needs to ensure optimal performance. Proper installation, testing, and maintenance practices maximize the value of these critical components while ensuring personnel safety and system reliability throughout their operational lifecycle.

FAQ

1. What distinguishes current transformers from other current sensing technologies?

Current transformers provide electrical isolation between primary and secondary circuits, ensuring operator safety while delivering accurate measurements. Unlike shunt resistors or Hall effect sensors, CTs do not introduce power losses in primary circuits and maintain consistent accuracy across wide current ranges without requiring external power supplies.

2. How do you calculate the correct current transformer ratio for a specific application?

Current transformer ratio calculation involves dividing the maximum expected primary current by the desired secondary current, typically 5 amperes for standard applications. The selected ratio should accommodate 120% of maximum load current to prevent saturation while maintaining operation within the linear accuracy range of the transformer.

3. What safety precautions are essential during current transformer installation and operation?

Secondary circuits must never operate in open-circuit conditions, as this creates dangerous voltages that can damage equipment and endanger personnel. Proper grounding of secondary circuits and installation of shorting blocks during maintenance ensure safe operation. Primary connections require appropriate torque specifications to prevent overheating and maintain electrical integrity.

Partner with Xi'an Xidian for Superior Current Transformer Solutions

Xi'an Xidian delivers precision-engineered current transformer solutions backed by decades of manufacturing excellence and global project experience. Our technical team provides expert guidance on transformer selection, custom ratio configurations, and application-specific modifications to meet your exact monitoring requirements. Whether you need standard units or customized solutions, our comprehensive product range and fast delivery capabilities support project timelines while ensuring quality and reliability. Contact our specialists at serina@xaxd-electric.com, amber@xaxd-electric.com, or luna@xaxd-electric.com to discuss your current transformer procurement needs and discover why leading companies worldwide trust Xi'an Xidian as their preferred current transformer supplier.

References

1. IEEE Standard C57.13-2016, "IEEE Standard Requirements for Instrument Transformers," Institute of Electrical and Electronics Engineers, New York, 2016.

2. International Electrotechnical Commission, "IEC 61869-2: Instrument transformers - Part 2: Additional requirements for current transformers," Geneva, Switzerland, 2012.

3. Blackburn, J.L. and Domin, T.J., "Protective Relaying: Principles and Applications," Fourth Edition, CRC Press, Boca Raton, Florida, 2014.

4. So, E. and Arseneau, R., "An analysis of the accuracy of current transformer calibration," IEEE Transactions on Instrumentation and Measurement, vol. 54, no. 4, pp. 1208-1213, 2005.

5. Kang, Y.C., Kang, S.H., and Park, J.K., "Compensation of the distortion in the secondary current caused by saturation and remanence in a CT," IEEE Transactions on Power Delivery, vol. 19, no. 4, pp. 1642-1649, 2004.

6. CIGRE Working Group B5.05, "Modern Techniques for Protecting, Controlling and Monitoring Power Systems," Technical Brochure 387, International Council on Large Electric Systems, Paris, France, 2009.