Modular APF Design: Easy Installation & Scalability

2026-01-04 15:33:25

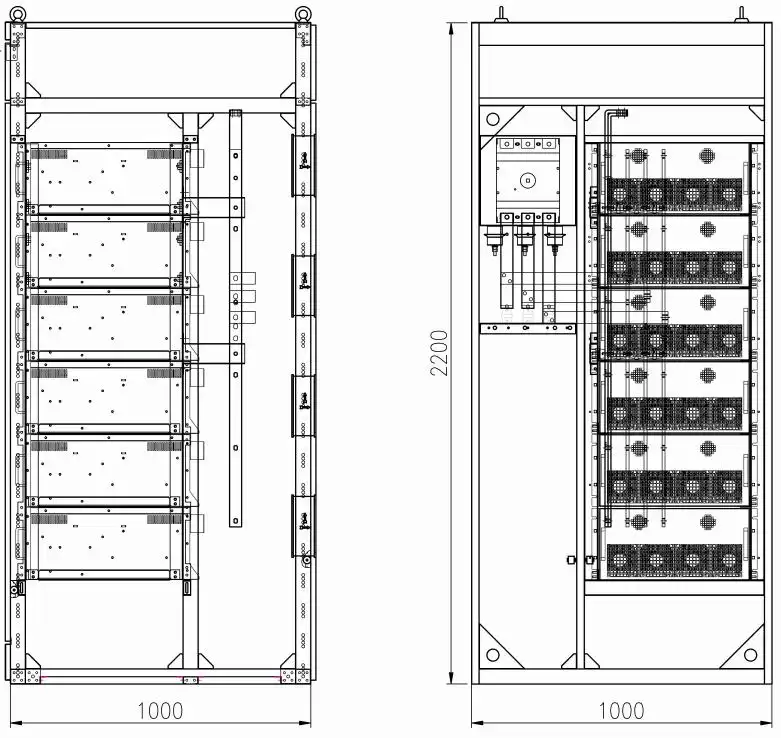

Modular Active Power Filter design revolutionizes power quality management by delivering unparalleled installation simplicity and scalability advantages. Unlike traditional monolithic systems, modular APF configurations allow facilities to deploy harmonic mitigation solutions incrementally while maintaining operational flexibility. The segmented architecture enables businesses to address current power quality challenges while preserving expansion capabilities for future growth, making these systems particularly valuable for industrial facilities requiring dynamic load management and cost-effective power quality solutions. Modular Active Power Filters represent a significant advancement over customary constant modulation innovations through their portioned, configurable engineering. These frameworks utilize free sifting modules that can be combined to accomplish craved control appraisals and execution determinations. Each module works independently, while contributing to the general framework's usefulness, making repetition and operational adaptability that conventional single-unit channels cannot match. The secluded approach employs rack- or wall-mounted units with autonomous control and control components, effectively into existing frameworks whereas giving real-time checking, versatile consonant concealment, and steady execution beneath shifting loads. System scalability emerges through parallel module connections that increase total filtering capacity without requiring complete Active Power Filter system replacement. Facilities can begin with minimal modules to address immediate harmonics concerns and expand capacity as electrical loads grow or power quality requirements become more stringent. This approach reduces initial capital expenditure while providing long-term flexibility for evolving industrial needs. Industrial situations show special challenges that secluded APF frameworks address through their characteristic plan focal points. Fabricating offices, information centers, and commercial complexes advantage from streamlined establishment forms that minimize operational disturbances whereas conveying quantifiable control quality improvements. Modular frameworks disentangle establishment through autonomous, plug-and-play modules that empower staged sending, decrease labor and commissioning time, lower integration complexity, and quicken return on speculation compared to conventional single-unit solutions. Modular APF innovation gives real-time consonant investigation, multi-frequency sifting, and solid stack versatility, guaranteeing steady control quality, ensuring touchy gear, lessening vitality misfortunes, and bringing down control figure punishments in mechanical facilities. Modular plans encourage component-level upkeep that minimizes benefit interferences and decreases lifecycle costs. Specialists can benefit person modules without being influenced by and large framework operation, empowering proactive upkeep methodologies that anticipate unforeseen disappointments. The standardized module plan streamlines saving parts stock while decreasing preparation needs for upkeep personnel. Understanding the qualifications between secluded and conventional sifting approaches makes a difference when experts make educated choices almost control quality ventures. The comparison includes specialized execution, financial considerations, and operational points of interest that affect long-term office operations. Modular APF frameworks adjust powerfully to changing loads through disseminated control, conveying exact consonant recompense. Their multi-module engineering progresses resistance to network vacillations and guarantees halfway operation amid upkeep, not at all like conventional single-unit APFs with settled parameters. Modular APFs lower add up to taking a toll on proprietorship through rearranged establishment, versatile extension, and simpler support. Staged speculation, progressed control figure, and decreased consonant twisting produce vitality investment funds and operational adaptability, supporting more grounded long-term returns. Successful measured APF execution requires cautious thought of facility-specific necessities, stack characteristics, and future extension plans. The determination prepare ought to assess current control quality challenge,s whereas foreseeing advancing electrical requests that may require extra sifting capacity. Load profile analysis forms the foundation for appropriate system sizing and configuration decisions. Facilities must evaluate harmonic distortion levels, reactive power requirements, and load diversity to determine optimal module quantities and ratings. The assessment should consider peak demand periods, equipment sensitivity levels, and existing power quality mitigation measures. Voltage range compatibility ensures seamless integration with existing electrical infrastructure. Modular systems must accommodate facility voltage levels while providing adequate protection for connected equipment. The evaluation should consider voltage fluctuation ranges and transient conditions that may affect Active Power Filter performance. Pre-installation planning reduces deployment risks while ensuring optimal system performance. Electrical studies should verify adequate space allocation, proper ventilation requirements, and appropriate electrical connections. The planning phase must address integration with existing power factor correction equipment and protective relay coordination. Commissioning procedures validate proper system operation while optimizing performance parameters for specific facility conditions. The process includes harmonic measurement verification, control system calibration, and protective device testing. Proper documentation ensures consistent maintenance procedures and troubleshooting capabilities. Xi'an Xidian Medium & Low Voltage Electric Co., Ltd. stands as one of China's premier manufacturing bases for medium and low-voltage electrical equipment, specializing in comprehensive power distribution solutions. Our extensive product portfolio encompasses power electronics solutions designed to address complex industrial power quality challenges through innovative modular technologies. Our modular APF systems incorporate rugged reliability features that ensure consistent performance in demanding industrial environments. The manufacturing process includes comprehensive quality control measures with 72-hour aging tests and 100% load validation before shipment. These rigorous testing procedures guarantee product reliability while minimizing field service requirements. Our plateau-type equipment meets operational requirements at altitudes up to 4,000 meters, while all technical specifications comply with national and industry standards. The robust design accommodates extreme environmental conditions while maintaining optimal filtering performance across diverse application scenarios. Our commitment to quality excellence is demonstrated through multiple industry certifications including ISO 9001, ISO 14001, CE, UL, and CCC compliance. These certifications validate our manufacturing processes, environmental management systems, and product safety standards that meet international requirements. Our solutions serve diverse industrial sectors including power engineering, steel and metallurgy, petrochemicals, rail transportation, and renewable energy applications. The proven track record across multiple industries demonstrates our capability to deliver customized, reliable solutions that address specific power quality challenges. Modular APF systems deliver measurable benefits across diverse industrial applications, from manufacturing facilities to critical infrastructure installations. These real-world implementations demonstrate the practical advantages of modular technology in addressing complex power quality challenges. CNC machines and automated assembly lines benefit significantly from modular APF installation through elimination of power factor penalties and protection against harmonic distortion. The systems handle surge currents up to 100 times rated capacity while maintaining consistent filtering performance. Manufacturing facilities report improved equipment reliability and reduced electrical maintenance costs following modular APF deployment. Utility substations utilize modular filtering technology to stabilize voltage conditions against harmonics generated by renewable energy inverters and intermittent generation sources. The adaptive filtering capability maintains grid stability while accommodating varying generation profiles from solar and wind installations. Hospitals and commercial complexes benefit from silent operation characteristics, with sound levels below 45dB that maintain comfortable environments. The flame-retardant capacitors meet NFPA 70 fire codes while providing reliable harmonic mitigation in space-constrained installations. These systems integrate seamlessly into existing electrical infrastructure without requiring extensive modifications. Modular APF design represents a transformative approach to industrial power quality management through its combination of installation simplicity, operational scalability, and maintenance efficiency. The technology addresses critical facility needs including harmonic mitigation, energy cost reduction, and equipment protection while providing flexibility for future expansion. Industrial facilities, utility installations, and commercial buildings benefit from improved power quality, reduced operational costs, and enhanced electrical system reliability. The modular architecture ensures long-term value through adaptable configurations that evolve with changing facility requirements, making these Active Power Filter systems essential components of modern power quality management strategies. A: Secluded APF frameworks utilize dispersed control calculations that ceaselessly screen electrical parameters and alter sifting capacity in real-time. When sudden stack increments happen, person modules consequently facilitate to give extra consonant remuneration whereas keeping up ideal control quality. The system's versatile engineering permits extra modules to actuate as required, guaranteeing reliable execution over shifting stack conditions without manual intervention. A: Yes, measured APF frameworks are planned to complement existing control calculate adjustment gear through facilitated control techniques. The progressed control frameworks communicate with existing capacitor banks and inactive VAR compensators to optimize generally control quality execution. This integration kills clashes between distinctive recompense strategies whereas maximizing the viability of both consonant sifting and receptive control compensation. A: Secluded APF frameworks suit a wide extend of mechanical voltage levels from 208V to 690V for low-voltage applications and can be arranged for medium-voltage establishments up to 35kV. The measured plan permits voltage customization through transformer setups and control framework programming. This adaptability guarantees compatibility with differing mechanical electrical frameworks whereas keeping up ideal sifting execution over all upheld voltage ranges. Xi'an Xidian combines decades of electrical engineering expertise with cutting-edge modular APF technology to deliver comprehensive power quality solutions for industrial applications. Our team of specialists provides customized system design, professional installation support, and ongoing maintenance services that ensure optimal performance throughout the equipment lifecycle. As a trusted Active Power Filter supplier, we understand the unique challenges facing modern industrial facilities and deliver solutions that improve operational efficiency while reducing energy costs. Our technical assistance and training programs reflect our creativity and cooperation beyond product delivery. We provide extensive consultations and performance demonstrations for facilities engineers, procurement managers, and decision-makers to examine our modular APF systems. Contact us at serina@xaxd-electric.com to discuss your specific power quality requirements and discover how our modular technology can enhance your facility's electrical performance. 1. Institute of Electrical and Electronics Engineers. "IEEE Standard 519-2014: Recommended Practice and Requirements for Harmonic Control in Electric Power Systems." IEEE Power & Energy Society, 2014. 2. Akagi, Hirofumi, Edson Watanabe, and Mauricio Aredes. "Instantaneous Power Theory and Applications to Power Conditioning." John Wiley & Sons, 2017. 3. Rashid, Muhammad H. "Power Electronics Handbook: Devices, Circuits, and Applications." Butterworth-Heinemann, 2018. 4. Singh, Bhim, Kamal Al-Haddad, and Ambrish Chandra. "A Review of Active Filters for Power Quality Improvement." IEEE Transactions on Industrial Electronics, Vol. 46, No. 5, October 1999. 5. Moreno-Munoz, Antonio. "Power Quality: Mitigation Technologies in a Distributed Environment." Springer-Verlag London, 2007. 6. International Electrotechnical Commission. "IEC 61000-3-12: Electromagnetic Compatibility - Limits for Harmonic Currents Produced by Equipment Connected to Public Low-voltage Systems." IEC Standards, 2011.

Understanding Modular Active Power Filter (APF) Design

Core Architecture and Technology

Scalability Through Modular Integration

The Benefits of Modular APF Design for Industrial Applications

Installation Efficiency and Reduced Downtime

Dynamic Harmonic Suppression Capabilities

Maintenance and Operational Benefits

Comparing Modular APF with Traditional APF Solutions

Technical Performance Differences

Economic and Operational Advantages

Practical Guide to Selecting and Implementing Modular APF Systems

System Selection Criteria

Implementation Best Practices

Xi'an Xidian: Excellence in Power Quality Solutions

Advanced Manufacturing Capabilities

Industry Certifications and Quality Assurance

Real-World Applications

Industrial Manufacturing Environments

Electrical Substation Applications

Commercial Building Retrofits

Conclusion

Frequently Asked Questions

Q1: How do modular APF systems handle sudden load increases without affecting performance?

Q2: Can modular APF systems integrate with existing power factor correction equipment?

Q3: What voltage ranges do modular APF systems support for industrial applications?

Partner with Xi'an Xidian for Advanced Power Quality Solutions

References