How AHF Prevents Resonance in Commercial Buildings?

2025-12-30 15:58:51

Active Harmonic Filter technology provides a comprehensive solution for preventing resonance in commercial buildings through real-time monitoring and dynamic compensation of electrical harmonics. These advanced systems continuously analyze power quality conditions and inject precisely calibrated currents to neutralize distortions before they can amplify through system resonance. By addressing both voltage and current harmonics simultaneously, these filters maintain stable electrical conditions across varying load profiles, protecting sensitive equipment while optimizing energy efficiency in modern commercial facilities. Harmonic reverberation speaks to one of the most challenging control quality issues confronting commercial office administrators nowadays. This wonder happens when nonlinear loads make misshapen electrical waveforms that associated dangerously with the common capacitances and inductances display in building electrical frameworks. The result is an enhancement impact that can seriously compromise hardware execution and framework reliability. Modern commercial buildings contain various harmonic-generating gadgets that contribute to reverberation conditions. Variable recurrence drives controlling HVAC frameworks, Driven lighting establishments, lift engine drives, and uninterruptible power supplies all deliver characteristic consonant marks. These nonlinear loads draw current in brief, serious spikes or maybe than smooth sinusoidal designs, making mutilations that proliferate throughout the electrical distribution system. When consonant frequencies adjust with the characteristic thunderous recurrence of the electrical framework, perilous intensification happens. This condition can increase consonant streams by components of 10 to 50 times their ordinary levels, leading to transformer overheating, capacitor bank failures, and premature hardware degradation. Fabricating offices report gear disappointments costing hundreds of thousands in wasted generation when reverberation conditions stay unaddressed. Active harmonic filter technology employs sophisticated power electronics to actively counteract harmonic disturbances in real-time. Unlike passive solutions that can inadvertently create new resonance points, active systems adapt dynamically to changing load conditions while maintaining system stability. The center advantage of dynamic sifting lies in its persistent checking capabilities. Progressed current transformers and voltage sensors bolster real-time information to computerized flag processors that analyze consonant substance over all frequencies. Inside microseconds, the framework calculates the exact remuneration streams required to neutralize recognized mutilations. This fast reaction anticipates consonant aggregation that leads to reverberation conditions. Modern dynamic channels utilize brilliantly control calculations that naturally alter stipend methodologies based on framework conditions. These calculations can separate between different sorts of loads and their consonant marks, giving focused on relief for particular unsettling influence designs. The versatile nature guarantees ideal execution indeed as building loads alter all through day by day operational cycles. Contemporary active harmonic filters feature modular architectures that accommodate both rack-mounted and wall-mounted configurations. This design flexibility allows seamless integration into existing electrical rooms without requiring extensive modifications. The modular approach also enables capacity expansion as building loads grow, providing long-term scalability for evolving facility requirements. The implementation of active harmonic filtering delivers substantial improvements across multiple operational metrics that directly impact facility profitability and reliability. These benefits extend beyond simple harmonic mitigation to encompass broader power quality enhancement and operational efficiency gains. By keeping up clean control conditions, dynamic channels essentially extend the operational life of sensitive electronic hardware. Information centers report 40-60% decreases in server equipment disappointments after implementing comprehensive consonant relief. Additionally, healing centers encounter less disturbances to basic restorative hardware, improving persistent care quality while diminishing upkeep costs. Clean control interprets straightforwardly into vitality reserve funds through diminished misfortunes in transformers, cables, and turning gear. Commercial buildings regularly accomplish 5-15% diminishments in vitality utilization taking after dynamic channel installation. These investment funds compound over time, regularly giving total return on speculation inside 18-24 months of deployment. Active harmonic filters help facilities maintain compliance with IEEE 519 and IEC 61000 standards while improving power factor performance. Many utility companies impose penalties for poor power factor or excessive harmonic distortion, making active filtering a financially prudent investment. Manufacturing facilities report eliminating monthly power factor penalties ranging from $5,000 to $25,000 through proper harmonic management. Successful dynamic channel sending requires cautious planning and orderly execution to accomplish ideal execution. The establishment prepare starts with a comprehensive framework evaluation and proceeds through commissioning and continuous upkeep protocols. Effective consonant moderation begins with intensive control quality investigation utilizing specialized checking hardware. This evaluation recognizes particular consonant sources, reverberation frequencies, and stack characteristics that illuminate channel measuring and situation choices. Proficient investigation regularly uncovers different consonant sources that require facilitated moderation procedures for maximum effectiveness. Active channels are coordinated consistently with existing electrical dispersion frameworks through standardized association focuses. Establishment regularly requires 4-8 hours for smaller frameworks and can be completed amid planned upkeep windows to minimize operational disturbance. Appropriate establishing and security coordination guarantees secure, solid operation inside existing security systems. Regular support conventions guarantee maintained execution all through the filter's operational life. Month to month execution audits, quarterly calibration checks, and yearly comprehensive testing keep up ideal recompense exactness. Farther checking capabilities permit proactive recognizable proof of potential issues some time recently they affect framework performance. When evaluating harmonic mitigation options, facility managers must consider various technologies based on their specific operational requirements and system characteristics. Each approach offers distinct advantages and limitations that affect long-term performance and cost-effectiveness. Passive filters offer lower initial costs but create fixed resonance points that can become problematic as system loads change. Active filters provide superior flexibility and avoid resonance risks, making them ideal for dynamic commercial environments. The initial investment premium for active solutions typically pays for itself through improved reliability and reduced maintenance requirements. Comprehensive total cost of ownership analysis reveals that active harmonic filters deliver superior long-term value despite higher initial costs. Reduced equipment replacement costs, eliminated power factor penalties, and improved energy efficiency combine to provide attractive returns on investment. Manufacturing facilities report payback periods averaging 2-3 years when all benefits are considered. Xi'an Xidian Medium & Low Voltage Electric Co., Ltd. delivers comprehensive power quality solutions specifically designed for demanding commercial applications. Our active harmonic filter portfolio addresses the diverse needs of industrial plants, data centers, hospitals, and large commercial complexes through innovative technology and proven reliability. Our advanced filtering systems feature dynamic harmonic suppression capabilities that adapt to changing load conditions while maintaining exceptional resistance to grid fluctuations. The modular design philosophy enables both rack-mounted and wall-mounted configurations to suit any installation requirement. These features combine to deliver measurable energy cost reductions while ensuring rugged reliability in challenging operating environments. Real-world applications demonstrate the versatility and effectiveness of our solutions. Industrial plants eliminate power factor penalties in CNC machines and assembly lines while handling surge currents up to 100 times rated capacity. Substation installations stabilize voltage against harmonics and intermittent generation from renewable inverters. Commercial buildings retrofit aging systems in hospitals and shopping centers with silent operation below 45dB using flame-retardant capacitors that meet NFPA 70 fire codes. Our commitment to manufacturing excellence ensures consistent quality through rigorous testing protocols. Each system undergoes 72-hour aging tests and 100% load validation before shipment, backed by comprehensive certifications including ISO 9001, ISO 14001, CE, UL, and CCC standards. This attention to quality control delivers the reliability that commercial facility operators demand. Active harmonic filters represent the most effective solution for preventing resonance in commercial buildings while delivering comprehensive power quality improvements. The technology's ability to adapt dynamically to changing conditions makes it superior to passive alternatives, particularly in complex commercial environments with varying load profiles. The investment in active filtering technology pays dividends through improved equipment reliability, reduced energy costs, and enhanced operational efficiency. As commercial buildings become increasingly dependent on sensitive electronic equipment, proactive harmonic management through active filtering becomes essential for maintaining competitive operations. A: Modern active harmonic filters respond within microseconds to changing harmonic conditions through real-time digital signal processing. This rapid response time prevents harmonic accumulation and maintains stable power quality even during dynamic load transitions common in commercial facilities. A: Quality active harmonic filters typically operate reliably for 15-20 years in commercial environments with proper maintenance. The solid-state design eliminates many mechanical wear components found in traditional solutions, contributing to extended operational life and reduced maintenance requirements. A: Advanced active harmonic filter designs accommodate high-altitude installations up to 4,000 meters above sea level with appropriate derating factors. Specialized cooling systems and component selection ensure reliable operation in challenging environmental conditions while maintaining full harmonic compensation capabilities. Transform your commercial facility's power quality with Xi'an Xidian's advanced active harmonic filter technology. Our comprehensive solutions eliminate resonance issues while improving energy efficiency and equipment reliability across diverse applications. As a leading Active Harmonic Filter manufacturer, we provide customized solutions backed by decades of engineering expertise and proven performance in demanding commercial environments. Our technical team conducts thorough assessments to ensure optimal system design and performance for your specific requirements. Contact us at serina@xaxd-electric.com to schedule your power quality analysis and discover how our innovative filtering solutions can enhance your operational efficiency. 1. Institute of Electrical and Electronics Engineers. "IEEE Recommended Practice and Requirements for Harmonic Control in Electric Power Systems." IEEE Standard 519-2014. 2. International Electrotechnical Commission. "Electromagnetic Compatibility - Part 3-2: Limits for Harmonic Current Emissions." IEC 61000-3-2:2018. 3. National Fire Protection Association. "National Electrical Code." NFPA 70, Article 450 - Transformers and Transformer Vaults, 2023 Edition. 4. Arrillaga, Jos and Neville R. Watson. "Power System Harmonics: Analysis and Design." John Wiley & Sons, Second Edition, 2003. 5. Dugan, Roger C., Mark F. McGranaghan, Surya Santoso, and H. Wayne Beaty. "Electrical Power Systems Quality." McGraw-Hill Professional, Third Edition, 2012. 6. Singh, Bhim, Kamal Al-Haddad, and Ambrish Chandra. "A Review of Active Filters for Power Quality Improvement." IEEE Transactions on Industrial Electronics, Vol. 46, No. 5, October 1999.

Understanding Harmonic Resonance in Commercial Buildings

Common Sources of Harmonics in Commercial Environments

The Resonance Amplification Effect

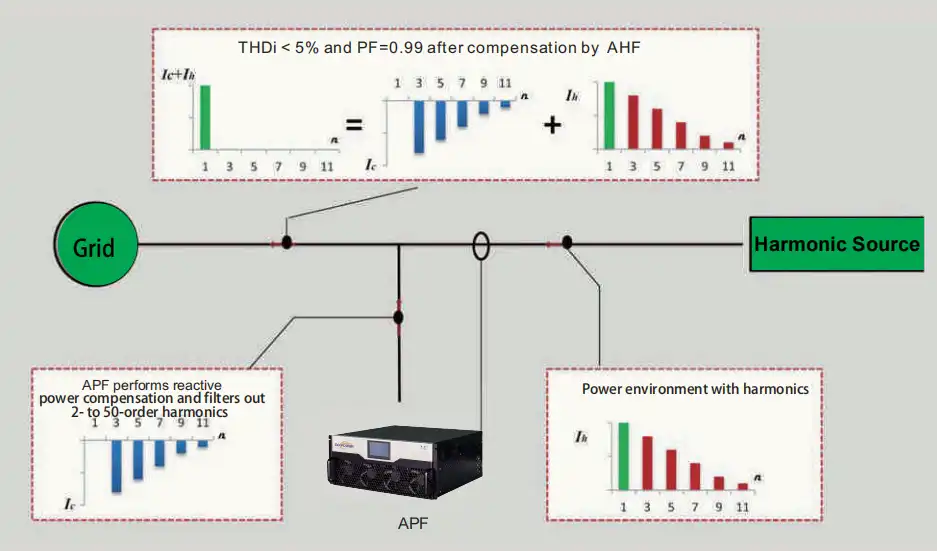

How Active Harmonic Filters Work to Prevent Resonance?

Real-Time Harmonic Detection and Compensation

Adaptive Control Algorithms

Modular Design Flexibility

Benefits of Using Active Harmonic Filters in Commercial Buildings

Enhanced Equipment Reliability and Lifespan

Energy Efficiency and Cost Reduction

Regulatory Compliance and Power Factor Improvement

Installation and Maintenance Guide for Active Harmonic Filters

Pre-Installation Assessment and System Design

Integration with Existing Electrical Infrastructure

Ongoing Maintenance and Performance Optimization

Comparing Active Harmonic Filters with Other Solutions

Active vs. Passive Harmonic Filtering

Cost-Benefit Analysis for Commercial Applications

Xi'an Xidian Active Harmonic Filter Solutions

Conclusion

Frequently Asked Questions

Q1: How quickly can active harmonic filters respond to changing harmonic conditions?

Q2: What is the typical lifespan of an active harmonic filter in commercial applications?

Q3: Can active harmonic filters operate effectively in high-altitude commercial installations?

Partner with Xi'an Xidian for Superior Harmonic Mitigation Solutions

References