XKGKL Dry-type Air Core Current Limiting Reactor

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1.XKGKL Dry-Type Air Core Current Limiting Reactor: Engineered for Grid Stability & Efficiency

In modern power systems, managing fault currents and enhancing grid reliability is critical. The XKGKL Dry-Type Air Core Current Limiting Reactor offers a robust solution by limiting short-circuit currents, protecting equipment, and maintaining system stability. Designed for medium/low-voltage networks, this reactor combines advanced engineering with energy-efficient performance, making it ideal for utilities, industrial plants, and renewable energy projects.

|

|

|

|

|

|

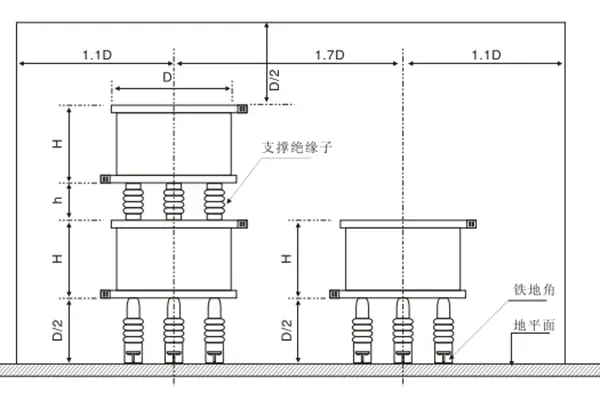

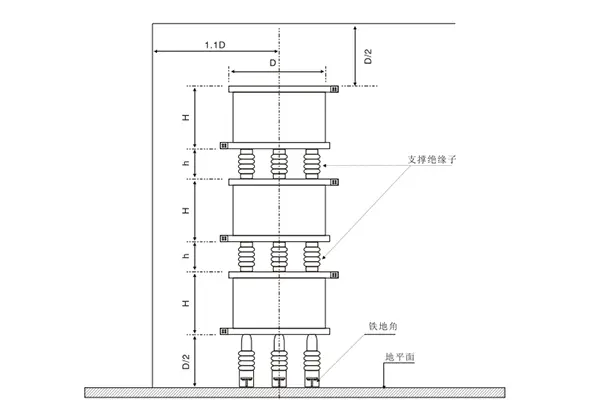

2.Technical Specifications

- Voltage Rating: 6 kV to 36 kV

- Impedance Range: 6–100 mΩ (customizable up to 500 mΩ)

- Current Capacity: 200 A to 5000 A

- Standards Compliance: IEC 60076-6, IEEE C57.21, CE, UL, CCC

- Thermal Class: H-class insulation (continuous operation at 155°C)

- Noise Level: <65 dB at 1m distance

- Losses: ≤0.03% at full load

| Model | Rated Current | Rated Voltage | Rated Reactance Ratio | Three-Phase Through-Capacity | Single-Phase Reactive Power Capacity | Short-Time Withstand Current | Peak Dynamic Withstand Current | Rated Inductance | Dimensions (Outer Diameter D × Height H) | Single-Phase Loss | Single-Phase Weight | Installation Diameter |

| A | kV | % | kvar | kvar | kv | kv | mH | mm | W | kg | ||

|

XKGKL-10-800-4 |

800 |

10 |

4 |

3×4618.8 |

184.8 |

20 |

51 |

0.919 |

Φ950/550 |

4525 |

300 |

1010 |

|

XKGKL-10-800-5 |

800 |

10 |

5 |

3×4618.8 |

230.9 |

16 |

40.8 |

1.149 |

Φ1000/570 |

5190 |

342 |

1050 |

|

XKGKL-10-800-6 |

800 |

10 |

6 |

3×4618.8 |

377.1 |

13.4 |

34.17 |

1.378 |

Φ1090/570 |

5807 |

379 |

1090 |

|

XKGKL-10-800-8 |

800 |

10 |

8 |

3×4618.8 |

369.5 |

10 |

25.5 |

1.838 |

Φ1140/600 |

6965 |

458 |

840 |

|

XKGKL-6-1000-4 |

1000 |

6 |

4 |

3×3464.1 |

138.6 |

25 |

63.75 |

0.441 |

Φ1110/580 |

3959 |

246 |

860 |

|

XKGKL-6-1000-5 |

1000 |

6 |

5 |

3×3464.1 |

173.2 |

20 |

51 |

0.551 |

Φ1160/600 |

4554 |

276 |

880 |

|

XKGKL-6-1000-6 |

1000 |

6 |

6 |

3×3464.1 |

207.2 |

16.7 |

42.58 |

0.662 |

Φ1200/620 |

5090 |

308 |

990 |

|

XKGKL-6-1000-8 |

1000 |

6 |

8 |

3×3464.1 |

277.1 |

12.5 |

31.88 |

0.882 |

Φ1240/650 |

5691 |

385 |

1060 |

|

XKGKL-6-1000-10 |

1000 |

6 |

10 |

3×3464.1 |

346.4 |

10 |

25.5 |

1.103 |

Φ990/600 |

6512 |

445 |

970 |

|

XKGKL-10-1000-4 |

1000 |

10 |

4 |

3×5773.5 |

230.9 |

25 |

63.75 |

0.735 |

Φ1010/630 |

5076 |

347 |

1010 |

|

XKGKL-10-1000-5 |

1000 |

10 |

5 |

3×5773.5 |

288.7 |

20 |

51 |

0.919 |

Φ1030/660 |

539 |

394 |

1050 |

|

XKGKL-10-1000-6 |

1000 |

10 |

6 |

3×5773.5 |

346.4 |

16.7 |

42.58 |

1.103 |

Φ1140/680 |

6511 |

455 |

1075 |

|

XKGKL-10-1000-8 |

1000 |

10 |

8 |

3×5773.5 |

461.9 |

12.5 |

31.88 |

1.47 |

Φ12500/710 |

7815 |

531 |

1100 |

|

XKGKL-10-1000-10 |

1000 |

10 |

10 |

3×5773.5 |

577.4 |

10 |

25.5 |

1.838 |

Φ1120/650 |

9000 |

613 |

950 |

|

XKGKL-6-1500-4 |

1500 |

6 |

4 |

3×5196.2 |

207.8 |

37.5 |

95.36 |

0.294 |

Φ1160/680 |

4350 |

343 |

1000 |

|

XKGKL-6-1500-5 |

1500 |

6 |

5 |

3×5196.2 |

259.8 |

30 |

76.5 |

0.368 |

Φ1200/710 |

5234 |

398 |

1050 |

|

XKGKL-6-1500-6 |

1500 |

6 |

6 |

3×5196.2 |

311.8 |

25 |

63.75 |

0.441 |

Φ1225/750 |

5828 |

453 |

1110 |

|

XKGKL-6-1500-8 |

1500 |

6 |

8 |

3×5196.2 |

415.7 |

18.8 |

47.82 |

0.588 |

Φ1250/790 |

7182 |

543 |

1190 |

|

XKGKL-6-1500-10 |

1500 |

6 |

10 |

3×5196.2 |

519.6 |

12.5 |

31.88 |

0.735 |

Φ1100/660 |

8276 |

632 |

1090 |

|

XKGKL-10-1500-4 |

1500 |

10 |

4 |

3×8660.3 |

346.4 |

37.5 |

95.63 |

0.49 |

Φ1150/680 |

6331 |

467 |

1150 |

|

XKGKL-10-1500-5 |

1500 |

10 |

5 |

3×8660.3 |

433 |

30 |

76.5 |

0.613 |

Φ1200/700 |

7437 |

559 |

1190 |

|

XKGKL-10-1500-6 |

1500 |

10 |

6 |

3×8660.3 |

519.6 |

25 |

63.75 |

0.735 |

Φ1260/730 |

8061 |

632 |

1230 |

|

XKGKL-10-1500-8 |

1500 |

10 |

8 |

3×8660.3 |

629.8 |

18.8 |

47.82 |

0.98 |

Φ1340/750 |

9722 |

750 |

1250 |

|

XKGKL-10-1500-10 |

1500 |

10 |

10 |

3×6928.2 |

866 |

12.5 |

31.88 |

1.225 |

Φ1240/700 |

11550 |

914 |

1020 |

|

XKGKL-6-2000-4 |

2000 |

6 |

4 |

3×6928.2 |

277.1 |

50 |

127.5 |

0.221 |

Φ1300/730 |

5935 |

410 |

1110 |

|

XKGKL-6-2000-5 |

2000 |

6 |

5 |

3×6928.2 |

346.4 |

40 |

102 |

0.276 |

Φ1340/750 |

6748 |

472 |

1200 |

|

XKGKL-6-2000-6 |

2000 |

6 |

6 |

3×6928.2 |

415.7 |

33.4 |

85.17 |

0.331 |

Φ1380/770 |

1503 |

530 |

1250 |

|

XKGKL-6-2000-8 |

2000 |

6 |

8 |

3×6928.2 |

554.3 |

25 |

63.75 |

0.441 |

Φ1450/800 |

8984 |

624 |

1300 |

|

XKGKL-6-2000-10 |

2000 |

6 |

10 |

3×6928.2 |

629.3 |

20 |

51 |

0.551 |

Φ1170/750 |

10344 |

721 |

1128 |

3.Key Features & Benefits

1. Superior Fault Current Mitigation

By increasing system impedance during faults, the XKGKL reactor reduces short-circuit currents to safe levels, preventing equipment damage and downtime.

2. Energy-Efficient Design

The air-core construction eliminates iron losses, achieving 30% lower energy waste compared to traditional iron-core reactors.

3. Durable & Low Maintenance

Built with H-class insulation and corrosion-resistant aluminum windings, it ensures a 30+ year lifespan even in harsh environments (dust, humidity, high temperatures).

4. Smart Grid Ready

Modular designs and IoT-compatible monitoring options enable seamless integration into modern, automated grids.

5. Customizable Solutions

Tailor impedance, size, and coatings (e.g., seismic-proof, dust-resistant) for regional needs—from Middle Eastern deserts to urban substations.

4.Applications

Be used in a wide range of industries.

Industrial Plants

Eliminate power factor penalties in CNC machines and assembly lines while handling surge currents up to 100x rated capacity.

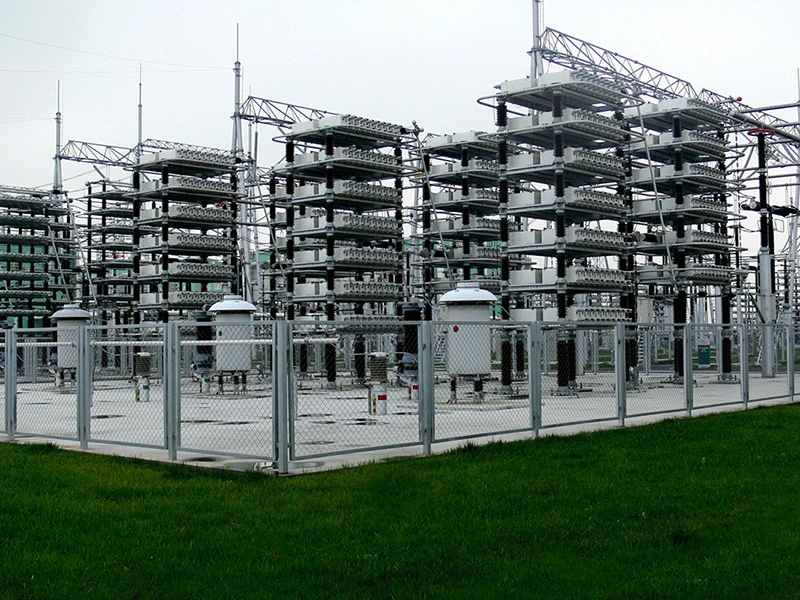

Substation

Stabilizes substation voltage against harmonics and intermittent generation from renewable inverters.

Commercial Buildings

Retrofit aging systems in hospitals or malls with silent (<45dB), flame-retardant capacitors that meet NFPA 70 fire codes.

5.How It Works?

The XKGKL Dry-Type Air Core Current Limiting Reactor uses a spiral-wound aluminum coil without an iron core. This design minimizes magnetic saturation, ensuring linear impedance during faults. When a short circuit occurs, the reactor’s impedance rises instantly, limiting current flow and safeguarding downstream equipment.

6.Quality Assurance & Certifications

- ISO 9001/14001 certified manufacturing.

- 3C Certification for low-voltage models.

- Rigorous testing: partial discharge, temperature rise, and impulse voltage tests.

- Patented coil fixation technology for vibration resistance.

7.Why Choose Us?

- R&D Leadership: Part of China’s 863 Program, with 15+ patents in reactor technology.

- Global Compliance: Meet IEC, IEEE.

- End-to-End Support: From design to after-sales service, backed by a 24/7 technical team.

- Proven Track Record: Trusted in 50+ infrastructure projects worldwide.

8.FAQ

1. How does the reactor handle high temperatures?

The H-class insulation allows continuous operation at 155°C, with forced-air cooling options for extreme conditions.

2. Can it be retrofitted into older grids?

Yes! Modular configurations simplify upgrades without major grid redesigns.

3. What’s the lead time for custom orders?

Standard units ship in 12 weeks; customized reactors take ≤16 weeks.

4. How does it reduce energy costs?

Lower losses (≤0.03%) cut operational expenses by up to $15,000/year per unit.

5. Is onsite installation support available?

Our engineers provide global installation guidance and troubleshooting.

9.Contact Us

Upgrade Your Grid’s Resilience Today!

Email xaxd_electric@163.com for a tailored quote or technical consultation. Let the XKGKL Dry-Type Air Core Current Limiting Reactor secure your network’s future.

10.Factory Show

11.Equipment Display

12.Application Cases

State Grid systems, power engineering, steel and metallurgy, petrochemicals, rail transportation, energy and water conservancy, construction, environmental protection, and renewable energy sectors

13.Team and Exhibition

Send Inquiry