Rack-mounted APF/AHF Active Power/Harmonic Filter

2.Power Grid Frequency:50Hz/60Hz

3.Real-time tracking: Maintains system power factor at 0.99 through linear, bidirectional (capacitive/inductive) compensation.

4.Active technology: Prevents resonance/harmonic amplification; efficient even under low-voltage conditions.

5.Modular design: Rack-mounted

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

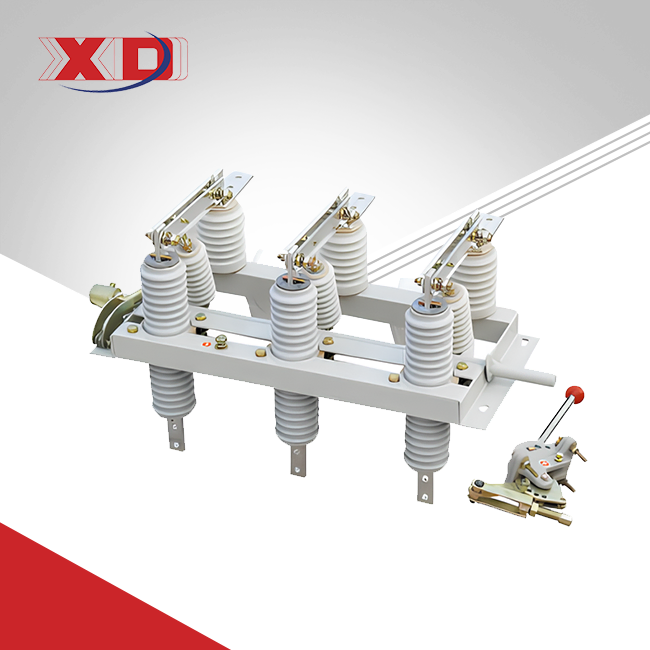

1.Rack-mounted APF/AHF Active Power/Harmonic Filter

In today’s power-intensive industries, the Rack-mounted APF/AHF Active Power/Harmonic Filter stands as a game-changer for managing harmonics, reactive power, and voltage stability. Designed for 400V±20% input systems, this advanced solution combines real-time tracking with adaptive compensation to maintain a power factor of 0.99. Its modular, rack-mounted design ensures seamless integration into diverse industrial setups while preventing harmonic resonance—even under challenging low-voltage conditions.

2.Technical Specifications

- Rated Input: 400V ±20%

- Frequency: 50Hz/60Hz

- Harmonic Filtering Accuracy: >95%

- Compensation Range: Linear, bidirectional (capacitive/inductive)

- Modular Capacity: 50A–3000A (expandable)

- Protection Grade: IP54

- Certifications: ISO 9001

|

Module Model |

||||

|

Models |

Compensation Capacity (A) |

System Voltage (V) |

Dimensions Width * Depth * Height (mm) |

Cooling System |

|

AHF-0.4-25A/4L-R(W) |

25 |

400 |

460*490*89 |

Forced air cooling |

|

AHF-0.4-50A/4L-R(W) |

50 |

400 |

460*490*89 |

Forced air cooling |

|

AHF-0.4-75A/4L-R(W) |

75 |

400 |

500*510*190 |

Forced air cooling |

|

AHF-0.4-100A/4L-R(W) |

100 |

400 |

500*550*240 |

Forced air cooling |

|

AHF-0.4-150A/4L-R(W) |

150 |

400 |

500*550*240 |

Forced air cooling |

|

AHF-0.5-100A/4L-R(W) |

100 |

500 |

495*675*275 |

Forced air cooling |

|

AHF-0.69-100A/4L-R(W) |

100 |

690 |

495*675*275 |

Forced air cooling |

|

Cabinet model |

||||

|

Models |

Compensation Capacity (A) |

System Voltage (V) |

Dimensions Width * Depth * Height (mm) |

Cooling System |

|

AHF-0.4-200A/4L-C |

200 |

400 |

1000*1000*2200 |

Forced air cooling |

|

AHF-0.4-250A/4L-C |

250 |

400 |

1000*1000*2200 |

Forced air cooling |

|

AAHF-0.4-300A/4L-C |

300 |

400 |

1000*1000*2200 |

Forced air cooling |

|

AHF-0.4-400A/4L-C |

400 |

400 |

1000*1000*2200 |

Forced air cooling |

|

AHF-0.4-500A/4L-C |

500 |

400 |

1000*1000*2200 |

Forced air cooling |

|

AHF-0.4-600A/4L-C |

600 |

400 |

1000*1000*2200 |

Forced air cooling |

|

AHF-0.5-200A/4L-C |

200 |

500 |

1000*1000*2200 |

Forced air cooling |

|

AHF-0.5-300A/4L-C |

300 |

500 |

1000*1000*2200 |

Forced air cooling |

|

AHF-0.5-400A/4L-C |

400 |

500 |

1000*1000*2200 |

Forced air cooling |

|

AHF-0.69-200A/4L-C |

200 |

690 |

1000*1000*2200 |

Forced air cooling |

|

AHF-0.69-300A/4L-C |

300 |

690 |

1000*1000*2200 |

Forced air cooling |

|

AHF-0.69-400A/4L-C |

400 |

690 |

1000*1000*2200 |

Forced air cooling |

|

|

220V Series |

380V Series |

500V Series |

690V Series |

|

Altitude |

<2000m, Usage should be de-rated according to the international standard IEC 3859-2 for altitudes above 2000 meters. |

|||

|

Ambient Temperature |

-10~+50 ℃ (derated above 40 ℃) |

|||

|

Relative Humidity |

≤ 90%, monthly minimum temperature 25 ℃, no condensation on the surface |

|||

|

Pollution Level |

Below Level III |

|||

|

Operating Voltage |

AC220V±20% |

AC380V(-20%~+20%) |

AC500V±20% |

AC690V(-20%~+15%) |

|

Operating Frequency |

50Hz/60Hz (45Hz~63Hz) |

|||

|

Rated Compensation Capacity |

25A |

25A, 50A, 75A, 100A, 150A |

100A |

|

|

Power Grid Structure |

L/N |

Three-phase three-wire, Three-phase four-wire |

||

|

Numbers in Parallel |

Not supported |

Unlimited |

||

|

System Efficiency |

≥97% |

|||

|

Switching Frequency |

32kHz |

16kHz |

12.8kHz |

|

|

Function Selection |

Harmonics |

Harmonics, Harmonics+Unbalanced |

||

|

Compensation Scope |

2~50 times, with adjustable compensation rate per time |

2-25 times, with adjustable compensation rate per time |

||

|

Harmonic Compensation Rate |

>92% |

|||

|

Full Response Time |

<10ms |

<40ms |

||

|

Noise |

≤60dB |

≤65dB |

||

|

Communication |

2*RS485 Communication Ports (Supports GPRS/WIFI) |

|||

|

Protection |

Overload, software/hardware over current, power grid over voltage/under voltage, power failure, over-temperature, frequency abnormality, short circuit protection |

Overload, software/hardware over current, power grid over voltage/under voltage, power grid voltage imbalance, power failure, over-temperature, frequency abnormality, short circuit protection |

||

|

Installation |

Rack-Mounted, Wall-Mounted |

Rack-Mounted |

||

|

Entry Line Method |

Rear Inlet (rack-mounted), Top Inlet (wall-mounted) |

Rear Line |

||

|

Protection Level |

IP20 |

|||

3.Key Features & Benefits

1. Dynamic Harmonic Suppression

Actively eliminates 2nd–50th order harmonics using patented IGBT switching technology.

2. Dual-Function Compensation

Simultaneously addresses harmonic distortion and reactive power imbalance.

3. Resistance to Grid Fluctuations

Stable operation in 300V–480V voltage ranges with <3ms response time.

4. Plug-and-Play Modularity

Hot-swappable modules enable capacity upgrades without downtime.

4.Applications

Be used in a wide range of industries.

Industrial Plants

Eliminate power factor penalties in CNC machines and assembly lines while handling surge currents up to 100x rated capacity.

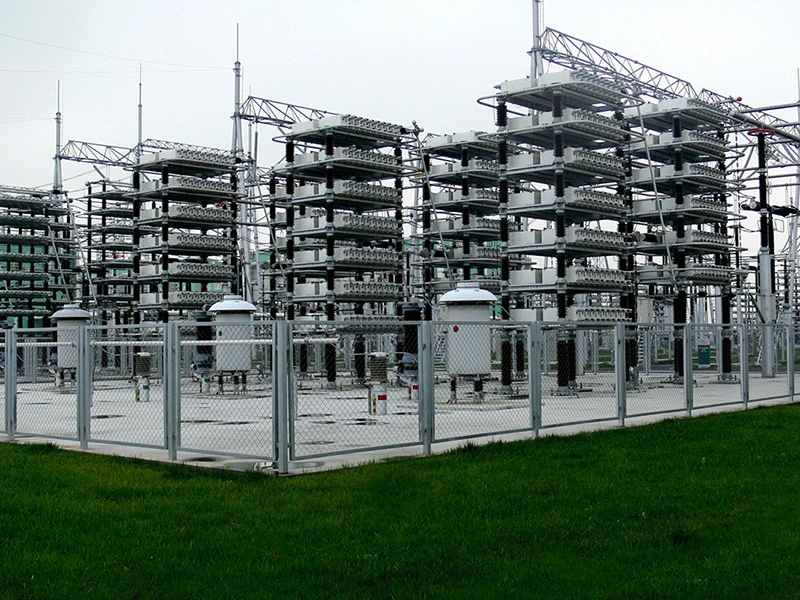

Substation

Stabilizes substation voltage against harmonics and intermittent generation from renewable inverters.

Commercial Buildings

Retrofit aging systems in hospitals or malls with silent (<45dB), flame-retardant capacitors that meet NFPA 70 fire codes.

5.How It Works?

1. Real-Time Analysis: DSP controllers monitor voltage/current waveforms.

2. Harmonic Detection: Identifies distortion patterns up to 20kHz.

3. Counteractive Injection: Generates inverse harmonics via IGBT inverters.

4. Closed-Loop Control: Maintains THDv <3% continuously.

6.Manufacturing & Quality Control

Our vertically integrated production includes Rack-mounted APF/AHF Active Power/Harmonic Filter:

- In-House Component Fabrication: IGBT modules, control boards

- 100+ Stage Testing: Thermal cycling, surge immunity, MIL-STD vibration tests

- Automated Assembly: Robotic soldering for consistency

7.Why Choose Us?

- 15+ Years Expertise: National 863 Program R&D partner

- Industry Recognition: "Top 10 Active Filter Brands" (2022)

- Compliance Assurance: 3C, ISO 14001,

- 50,000-Hour Reliability: MTBF-certified design

8.FAQs

Q: How quickly can this filter reduce harmonics in a steel plant?

A: Our system achieves <8% THDi within 1 power cycle (20ms).

Q: Can it handle variable frequency drives (VFDs) in oil/gas operations?

A: Yes, with dedicated algorithms for 6-pulse/12-pulse VFD harmonics.

Q: What’s the ROI timeline for a 1MW manufacturing facility?

A: Typical energy savings of 12–18% yield 2–3 year payback periods.

Q: Is remote monitoring included?

A: All units come with 24/7 IoT-based predictive maintenance alerts.

Q: Can we expand capacity post-installation?

A: Easily add modules via the rack’s N+1 redundant slots.

9.Contact Us

Contact Our Power Quality Team about Rack-mounted APF/AHF Active Power/Harmonic Filter.

Email: xaxd_electric@163.com

10.Factory Show

11.Equipment Display

12.Application Cases

State Grid systems, power engineering, steel and metallurgy, petrochemicals, rail transportation, energy and water conservancy, construction, environmental protection, and renewable energy sectors

13.Team and Exhibition

Send Inquiry