24kV Indoor Current Transformer

2.Frequency:50/60Hz

3.Rated primary current:20~3150A

4.Rated secondary current:5 or 1A

5.Standard:GB 20840.2-2014/IEC 61869-1 & 61869-2

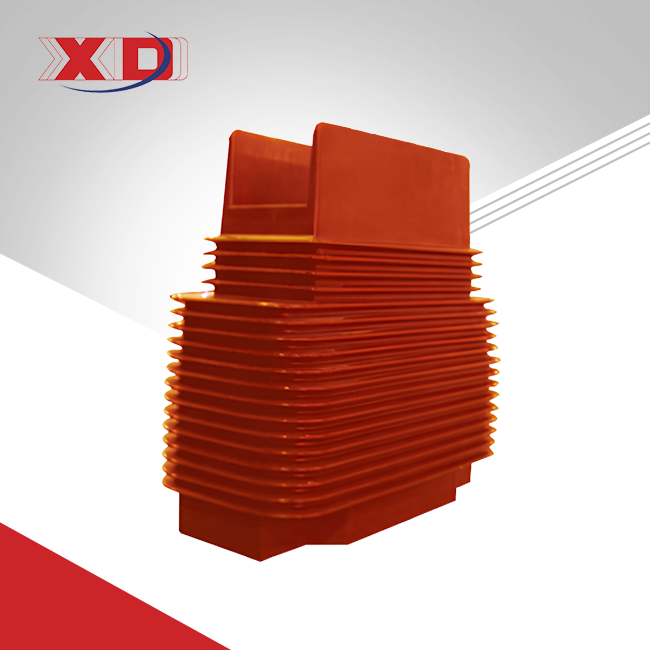

6.The transformer is epoxy resin cast fully-enclosed electromagnetic.It features high accuracy, large capacity, and stable performance.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1.24kV Indoor Current Transformer: Precision & Reliability for Modern Power Systems

When upgrading or maintaining high-voltage electrical systems, you need equipment that delivers accuracy and durability. The 24kV Indoor Current Transformer is engineered to meet these demands, offering exceptional performance in grid infrastructure, renewable energy integration, and industrial power distribution. Designed for indoor installations, this transformer ensures precise current measurement while withstanding harsh environmental conditions like temperature fluctuations and humidity. With compliance to IEC 61869-1/2 and GB 20840.2-2014 standards, it’s a trusted solution for utilities and industries worldwide.

2.Technical Specifications

- Input Voltage: 24kV

- Output Voltage: 10kV

- Frequency: 50/60Hz (dual-rated)

- Primary Current Range: 20–3150A

- Secondary Current: 5A or 1A

- Accuracy Class: 0.2/0.5

- Insulation: Epoxy resin cast, fully enclosed

- Standards: IEC 61869-1 & 61869-2, GB 20840.2-2014

| Rated primary current(A) | Rated secondary current(A) | Class combination | Rated secondary output (VA) | Short-time themal current(KA/S) | Rated dynamic current(KA) |

| 20-150 | 5 or 1A | 0.2S/10P10 0.5/10P10 0.2/0.5/10P10 0.2S/0.5/10P15 | 15/20 15/20 15/15/20 15/15/15 | 150I1n | 375I1n |

| 200 | 31.5 | 80 | |||

| 300 | 45 | 112.5 | |||

| 400 | |||||

| 500 | |||||

| 600 | 20/30 20/30 20/20/30 20/20/20 | 20/30 20/30 20/20/30 20/20/20 | 63 | 130 | |

| 800 | |||||

| 1000 | 80 | ||||

| 1200 | |||||

| 1250 | |||||

| 1500 | 100 | ||||

| 2000 | |||||

| 2500 | |||||

| 3000 | |||||

| 3150 |

3.Key Features & Benefits

1. High Accuracy & Stability

Achieve precise current measurement with Class 0.2 accuracy, ideal for metering and protection relays. The epoxy resin insulation ensures minimal partial discharge (<10pC), enhancing long-term reliability.

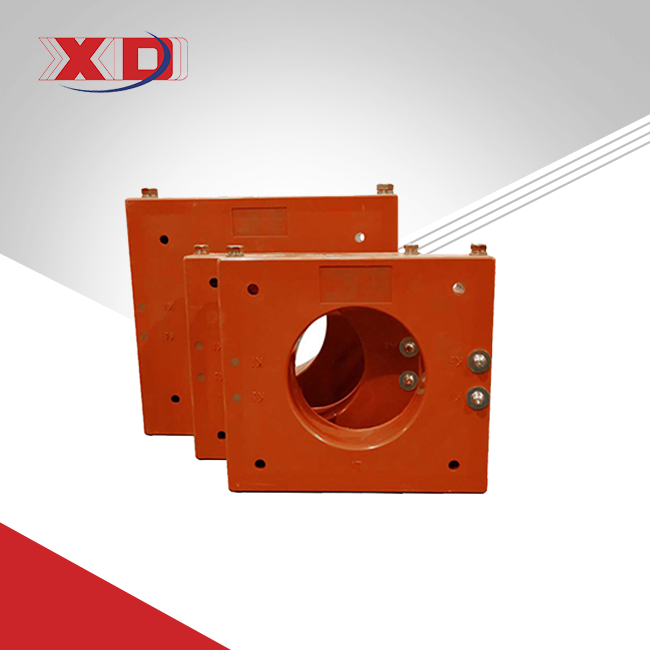

2. Robust Construction

Built for demanding environments, the transformer operates seamlessly between -40°C to +70°C. Its fully enclosed design resists dust, moisture, and corrosion—perfect for coastal or polluted indoor settings.

3. Flexible Customization

Need dual-ratio outputs or compact dimensions for space-constrained substations? We offer tailored designs to match your grid’s unique requirements.

4. Low Maintenance Costs

With high short-circuit withstand (25kA for 3s) and thermal stability, this product minimizes downtime and repair expenses.

4.Applications

Be used in a wide range of industries.

Industrial Plants

Eliminate power factor penalties in CNC machines and assembly lines while handling surge currents up to 100x rated capacity.

Substation

Stabilizes substation voltage against harmonics and intermittent generation from renewable inverters.

Commercial Buildings

Retrofit aging systems in hospitals or malls with silent (<45dB), flame-retardant capacitors that meet NFPA 70 fire codes.

5.Design & Working Principle

The transformer uses electromagnetic induction to scale high primary currents (up to 3150A) to standardized secondary outputs (5A or 1A). Its epoxy resin cast structure eliminates air gaps, preventing internal discharges and ensuring consistent performance. The core is optimized for low-loss operation, even under harmonic-rich loads.

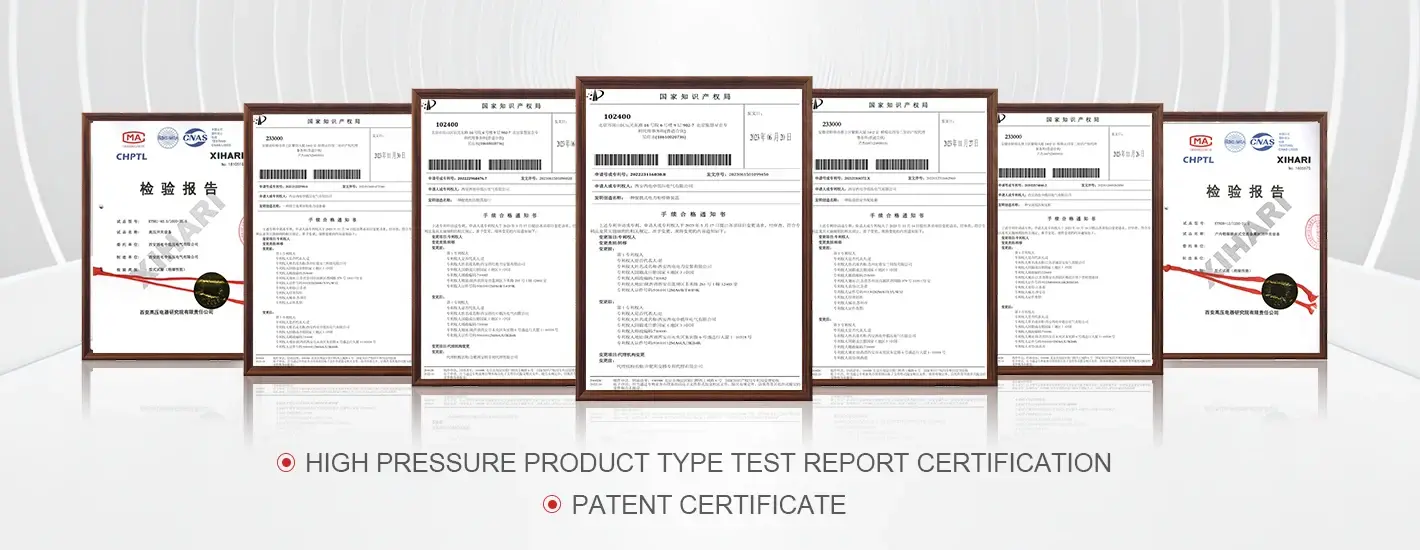

6.Manufacturing & Quality Control

Every 24kV Indoor Current Transformer undergoes rigorous testing:

- Material Screening: High-grade silicon steel and copper windings.

- Partial Discharge Tests: <10pC at 24kV.

- Thermal Cycling: Validated for extreme temperature resilience.

- Certifications: ISO 9001.

7.Why Choose Us?

- Expertise: Developed under China’s National 863 Program, backed by 15+ patents.

- Sustainability: Eco-friendly manufacturing aligned with RoHS and REACH.

- End-to-End Support: From technical consultation to 24/7 after-sales service.

8.FAQs

1. How does the epoxy resin insulation improve performance?

It prevents moisture ingress and partial discharges, ensuring stability in humid or corrosive environments.

2. Can this transformer work with legacy 50Hz systems?

Yes—it’s dual-rated for 50Hz/60Hz, making retrofits seamless.

3. How long is the lead time for customized designs?

Standard units ship in 4–6 weeks; custom orders require 6 weeks.

9.Contact Us

Email: xaxd_electric@163.com

Let’s discuss how our 24kV Indoor Current Transformer can optimize your power systems!

10.Factory Show

11.Equipment Display

12.Application Cases

State Grid systems, power engineering, steel and metallurgy, petrochemicals, rail transportation, energy and water conservancy, construction, environmental protection, and renewable energy sectors

13.Team and Exhibition

Send Inquiry