Oil-immersed Current Transformer

2.Frequency:50Hz

3.Power frequency withstand voltage:230/510/680kV

4.Rated primary current:4000A

5.Standard:GB 20840.2-2014/IEC 61869-1 & 61869-2

6.The transformer is epoxy resin cast fully-enclosed electromagnetic.It features high accuracy, large capacity, and stable performance.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1.Oil-immersed Current Transformer: Reliable Power Measurement for Demanding Environments

When precision and durability matter in high-voltage transmission systems, our Oil-immersed Current Transformer stands as a trusted solution. Designed for voltages up to 110kV, this transformer combines epoxy resin casting with advanced oil-paper insulation to deliver unmatched accuracy (Class 0.2/0.5) and stability across extreme temperatures (-45°C to +50°C). Ideal for power grids, industrial plants, and smart energy projects, it ensures seamless integration with IoT-enabled monitoring systems while meeting IEC, IEEE, and ANSI standards.

2.Technical Specifications

- Input Voltage: 110kV, 35kV, 66kV

- Output Voltage: 11kV

- Frequency: 50Hz

- Power Frequency Withstand Voltage: 230kV/510kV/680kV

- Rated Primary Current: 4000A

- Compliance: GB 20840.2-2014, IEC 61869-1 & 61869-2

-

Transformer type LVBT-500W2 LVBT-330W2 LVBT-220W3 LVB-220W3 LVB-110W3 LVB-66W3 Highest system voltage(kV) 550 363 252 252 126 72.5 Rated freguency(Hz) 50 50 50 50 50 50 Power freguency withstand voltage(kV) 680 510 460 460 230 160 BIL, 1.2/50 us full ware(kV) 1175 950 / / / / Chopped test(kV) 1550 1175 1050 1050 550 350 Flashover distance(mm) 3930 2675 2195 2200 1200 1200 Creepage distance(mm) ≥13750 ≥11253 ≥7812 ≥7812 ≥3906 ≥2248 Rated primary current(A) 4000 4000 4000 4000 3000 3000 Rated secondary current(A) 5;1 5;1 5;1 5;1 5;1 5;1 Accuracy class(Upon request) 0.1;0.2S;0.5;5P;10P,TPY 0.1;0.2S;0.5;5P;10P,TPY 0.1:0.2S;0.5;5P;10P,TPY 0.2S;0.5;5P;10P 0.2S;0.5;5P;10P 0.2S:0.5;5P;10P Rated output(VA) 10-50 10-50 10-50 10-50 10-50 10-50 Instrument secutity factor(FS) 5;10 5;10 5;10 5;10 5;10 5;10 Rated accuracy limit factor 30 30 30 30 30 30 Rated Short-time current/3s (max)lth(kA) 63 63 63 63 50 50 Rated dynamic current(max)Idyn(kA) 160 160 160 160 125 125 Dimensions(mm) 1000*1200*6200 745*1127*4265 745*1060*3745 604*980*3650 535(604)*780(930)*2230(2370) 535(604)*780(930)*2230(2370) Mounting size(mm) 650*650 600*600 600*600 600*600 450*450 450*450 Net weight(kg) 2250 1000 800 500 480 480 Gross weight(kg) 3100 1350 1070 790 550 550

3.Key Features & Benefits

1. Built to Endure Harsh Conditions

- Extreme Climate Resilience: Operates flawlessly in deserts, coastal regions, and high-altitude areas (up to 3000m).

- Earthquake Resistance: Withstands seismic activity up to 8 degrees.

- Leak-Proof Design: Multi-layer sealing prevents oil leakage during thermal expansion.

2. Smart Grid Ready

- Compatible with digital substations and real-time diagnostics for proactive maintenance.

3. Precision Engineering

- Epoxy resin casting ensures mechanical strength and moisture resistance.

- Oil-paper insulation maintains stability under heavy loads (up to 4000A).

4.Real-World Applications

Be used in a wide range of industries.

Industrial Plants

Eliminate power factor penalties in CNC machines and assembly lines while handling surge currents up to 100x rated capacity.

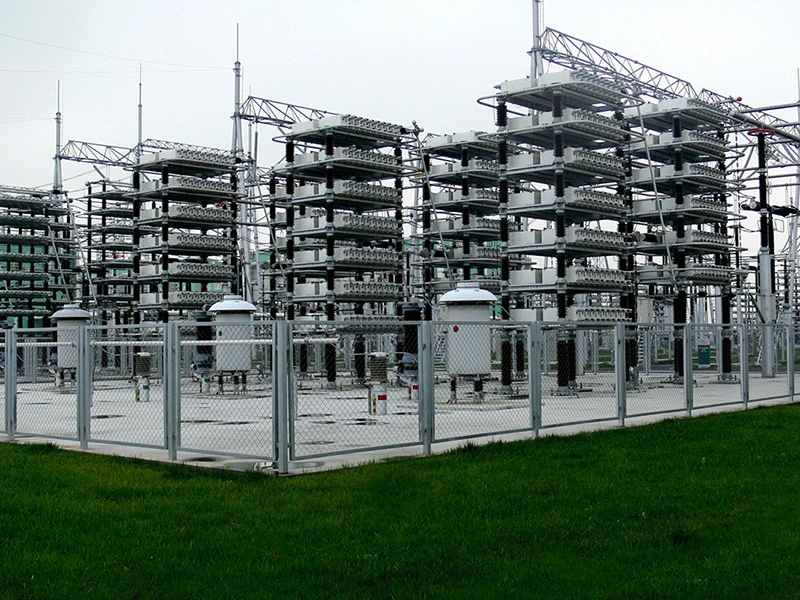

Substation

Stabilizes substation voltage against harmonics and intermittent generation from renewable inverters.

Commercial Buildings

Retrofit aging systems in hospitals or malls with silent (<45dB), flame-retardant capacitors that meet NFPA 70 fire codes.

5.How It Works?

The Oil-immersed Current Transformer uses electromagnetic induction to step down high currents for metering and protection. Its oil-immersed design dissipates heat efficiently, while capacitive grading ensures uniform voltage distribution. The metal expander accommodates oil volume changes, guaranteeing a 30+ year lifespan even in polluted (Class IV) areas.

6.Manufacturing & Quality Control

- ISO-Certified Production: From raw material sourcing to final testing.

- Rigorous Testing: Includes power frequency withstand, partial discharge, and thermal stability checks.

- Patented Designs: Developed through national R&D initiatives like the 863 Program.

7.Why Choose Us?

- 30+ Years Expertise: Trusted by global utilities and grid operators.

- Certifications: ISO 9001, ISO 14001.

- Custom Solutions: Tailored designs for seismic zones, arctic climates, or compact urban substations.

- 24/7 Support: From installation guidance to emergency troubleshooting.

8.FAQs

1. How often should I maintain the transformer?

Annual inspections are sufficient for most environments. In coastal/high-salinity areas, bi-annual checks are recommended.

2. Are your products compliant with IEC 61869?

Yes, all units exceed IEC 61869 and IEEE C57.13 requirements.

3. Can you customize for -45°C environments?

Absolutely. We use low-temperature alloys and anti-icing coatings for Arctic-grade reliability.

4. How do you prevent oil leakage?

Triple-sealed gaskets and pressure-relief valves ensure leak-proof operation.

9.Contact Us

Email xaxd_electric@163.com to discuss your Oil-immersed Current Transformer project needs. Let’s build a safer, smarter grid together!

10.Factory Show

11.Equipment Display

12.Application Cases

State Grid systems, power engineering, steel and metallurgy, petrochemicals, rail transportation, energy and water conservancy, construction, environmental protection, and renewable energy sectors

13.Team and Exhibition

Send Inquiry