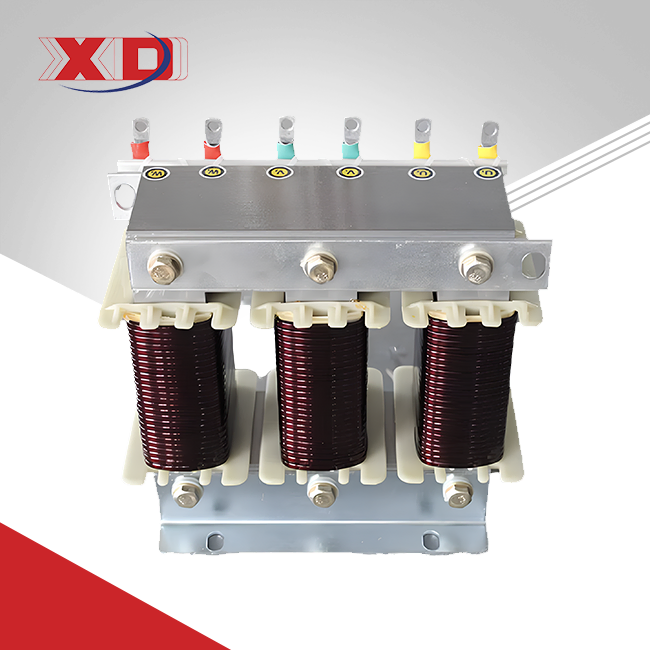

CKSC Dry-type Iron Core Series Reactor

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1.CKSC Dry-type Iron Core Series Reactor: Stabilize Your Grid with Precision

The power grid contains a significant number of harmonic sources such as rectifiers, converters, and frequency converters. The high-order harmonics they generate can severely jeopardize the safe operation of the main transformer and other electrical equipment in the system. Filter reactors are widely used in high and low-voltage filter cabinets, connected in series with filter capacitors. Tuned to a specific resonant frequency, they absorb harmonic currents of corresponding frequencies in the grid. Depending on the on-site harmonic conditions, they can eliminate the 3rd, 5th, 7th, 11th, 13th, and higher-order harmonics. The series connection of filter reactors and capacitors not only effectively absorbs grid harmonics but also improves the system's power factor, playing a significant role in ensuring the safe operation of the system.The CKSC Dry-type Iron Core Shunt Reactor offers a robust solution to these challenges.

|

|

|

2.Technical Specifications

- Rated Voltage: 6kV–35kV

- Efficiency: >99% at full load

- Noise Level: <65 dB (Premium Line)

- Insulation Class: H-grade (180°C)

- Certifications: IEC 60076-6, ISO 9001/14001

- Lifespan: 25+ years with proper maintenance

|

Type |

Capacitance voltage |

External dimensions(L*W*H) |

Installation dimensions(D*E) |

Installation diameter |

Approximate total weight(KG) |

|

CKSC-6/10-6% |

11√3KV |

675*350*620max |

430*280 |

13*26 |

145 |

|

CKSC-9/10-6% |

675*350*670max |

430*280 |

13*26 |

160 |

|

|

CKSC-12/10-6% |

675*350*740max |

430*280 |

13*26 |

175 |

|

|

CKSC-15/10-6% |

720*350*680max |

430*280 |

13*26 |

195 |

|

|

CKSC-18/10-6% |

720*350*740max |

430*280 |

13*26 |

210 |

|

|

CKSC-21/10-6% |

720*350*770max |

430*280 |

13*26 |

220 |

|

|

CKSC-24/10-6% |

720*350*800max |

430*280 |

13*26 |

230 |

|

|

CKSC-27/10-6% |

780*400*750max |

500*320 |

13*26 |

270 |

|

|

CKSC-30/10-6% |

780*400*810max |

500*320 |

13*26 |

295 |

|

|

CKSC-36/10-6% |

780*400*870max |

500*320 |

13*26 |

315 |

|

|

CKSC-42/10-6% |

825*400*870max |

530*320 |

13*26 |

375 |

|

|

CKSC-45/10-6% |

825*400*870max |

530*320 |

13*26 |

380 |

|

|

CKSC-48/10-6% |

825*400*870max |

530*320 |

13*26 |

380 |

|

|

CKSC-54/10-6% |

825*400*930max |

530*320 |

13*26 |

405 |

|

|

CKSC-60/10-6% |

825*400*890max |

530*320 |

13*26 |

430 |

|

|

CKSC-72/10-6% |

860*420*1055max |

540*340 |

13*26 |

505 |

|

|

CKSC-84/10-6% |

920*420*1070max |

580*340 |

13*26 |

595 |

|

|

CKSC-90/10-6% |

920*420*1070max |

580*340 |

13*26 |

600 |

|

|

CKSC-108/10-6% |

920*420*1130max |

580*340 |

13*26 |

640 |

|

|

CKSC-120/10-6% |

1025*420*1010max |

650*360 |

13*26 |

670 |

|

|

CKSC-144/10-6% |

1025*420*1110max |

650*360 |

13*26 |

730 |

|

|

CKSC-150/10-6% |

1190*450*1080max |

760*390 |

13*26 |

890 |

|

|

CKSC-162/10-6% |

1190*450*1080max |

760*390 |

13*26 |

910 |

|

|

CKSC-180/10-6% |

1250*500*1090max |

800*440 |

13*26 |

1060 |

|

|

CKSC-192/10-6% |

1250*500*1140max |

800*440 |

13*26 |

1100 |

|

|

CKSC-216/10-6% |

1300*600*1110max |

830*520 |

13*26 |

1200 |

|

|

CKSC-240/10-6% |

1300*600*1210max |

830*520 |

13*26 |

1260 |

|

|

CKSC-300/10-6% |

1400*600*1290max |

900*540 |

13*26 |

1700 |

|

|

CKSC-360/10-6% |

1400*600*1360max |

900*540 |

13*26 |

1735 |

|

|

CKSC-6/10-12% |

12√3KV |

675*350*620max |

430*280 |

13*26 |

145 |

|

CKSC-9/10-12% |

675*350*670max |

430*280 |

13*26 |

160 |

|

|

CKSC-15/10-12% |

720*350*740max |

430*280 |

13*26 |

210 |

|

|

CKSC-18/10-12% |

720*350*740max |

430*280 |

13*26 |

210 |

|

|

CKSC-24/10-12% |

780*400*750max |

500*320 |

13*26 |

270 |

|

|

CKSC-30/10-12% |

780*400*810max |

500*320 |

13*26 |

295 |

|

|

CKSC-36/10-12% |

780*400*870max |

500*320 |

13*26 |

315 |

|

|

CKSC-48/10-12% |

825*400*930max |

530*320 |

13*26 |

405 |

|

|

CSKC-54/10-12% |

825*400*930max |

530*320 |

13*26 |

405 |

|

|

CKSC-60/10-12% |

825*400*890max |

530*320 |

13*26 |

430 |

|

|

CSKC-72/10-12% |

860*420*1055max |

540*340 |

13*26 |

505 |

|

|

CSKC-84/10-12% |

920*420*1070max |

580*340 |

13*26 |

595 |

|

|

CKSC-90/10-12% |

920*420*1070max |

580*340 |

13*26 |

600 |

|

|

CKSC-96/10-12% |

920*420*1070max |

580*340 |

13*26 |

595 |

|

|

CKSC-108/10-12% |

920*420*1130max |

580*340 |

13*26 |

640 |

|

|

CKSC-120/10-12% |

1025*420*1010max |

650*360 |

13*26 |

670 |

|

|

CKSC-132/10-12% |

1025*420*1110max |

650*360 |

13*26 |

730 |

|

|

CKSC-144/10-12% |

1025*420*1110max |

650*360 |

13*26 |

730 |

|

|

CKSC-162/10-12% |

1190*450*1025max |

760*390 |

13*26 |

870 |

|

|

CKSC-168/10-12% |

1190*450*1060max |

760*390 |

13*26 |

890 |

|

|

CKSC-180/10-12% |

1250*500*1090max |

800*440 |

13*26 |

1060 |

|

|

CKSC-192/10-12% |

1250*500*1170max |

800*440 |

13*26 |

1120 |

|

|

CKSC-240/10-12% |

1300*600*1160max |

830*520 |

13*26 |

1250 |

|

|

CKSC-288/10-12% |

1300*600*1300max |

830*520 |

13*26 |

1390 |

|

|

CKSC-360/10-12% |

1400*600*1320max |

900*540 |

13*26 |

1700 |

|

|

CKSC-432/10-12% |

1500*650*1420max |

950*550 |

13*26 |

1920 |

|

|

CKSC-480/10-12% |

1500*650*1500max |

950*550 |

13*26 |

2000 |

|

|

CKSC-600/10-12% |

1600*720*1460max |

(515+515)*600 |

13*26 |

2520 |

|

|

CKSC-720/10-12% |

1600*720*1630max |

(515+515)*600 |

13*26 |

2820 |

|

|

CKSC-54/35-6% |

35KV |

1400*1080max*1130max |

950*500 |

13*26 |

700 |

|

CSKC-72/35-6% |

1450*1120max*1200max |

1000*500 |

13*26 |

820 |

|

|

CKSC-90/35-6% |

1600*1140max*1180max |

1090*500 |

13*26 |

950 |

|

|

CKSC-120/35-6% |

1600*1150max*1260max |

1110*550 |

13*26 |

1200 |

|

|

CKSC-144/35-6% |

1600*1150max*1360max |

1110*550 |

13*26 |

1280 |

|

|

CKSC-180/35-6% |

1750*1220max*1280max |

1210*620 |

13*26 |

1580 |

|

|

CKSC-216/35-6% |

1750*1220max*1380max |

1210*620 |

13*26 |

1670 |

|

|

CKSC-240/35-6% |

1750*1220max*1430max |

1210*620 |

13*26 |

1750 |

|

|

CKSC-288/35-6% |

1850*1240max*1410max |

1000*620 |

13*26 |

2050 |

|

|

CKSC-360/35-6% |

1850*1240max*1550max |

1000*620 |

13*26 |

2270 |

|

|

CKSC-432/35-6% |

1900*1250max*1650max |

1020*620 |

13*26 |

2600 |

|

|

CKSC-540/35-6% |

2000*1260max*1640max |

1070*650 |

13*26 |

3100 |

|

|

CKSC-600/35-6% |

2000*1260max*1740max |

1070*650 |

13*26 |

3250 |

|

|

CKSC-720/35-6% |

2150*1300max*1750max |

1180*700 |

13*26 |

3950 |

|

|

CKSC-864/35-6% |

2150*1300max*1850max |

1180*700 |

13*26 |

4150 |

|

|

CKSC-1080/35-6% |

2150*1300max*1940max |

1180*700 |

13*26 |

4520 |

|

|

CKSC-1200/35-6% |

2200*1340max*2000max |

1180*800 |

13*26 |

4800 |

|

|

CKSC-1400/35-6% |

2300*1350max*2100max |

1250*900 |

13*26 |

5600 |

3.Key Features & Advantages

1. Ultra-Low Noise Operation

Unlike traditional oil-cooled reactors, the product uses a segmented air-gap design with high-temperature adhesives. This reduces core vibration, keeping noise below 75 dB—ideal for urban substations.

2. Epoxy-Resin Encapsulated Coils

Coils are vacuum-cast with flame-retardant epoxy resin and reinforced with glass fiber. This ensures:

- Resistance to humidity, dust, and chemical corrosion

- High mechanical strength to withstand thermal shocks

- Partial discharge levels <5 pC for enhanced safety

3. Energy-Efficient Performance

With core losses reduced by 30% compared to conventional models, this reactor lowers operational costs while maintaining grid voltage stability. Its low-temperature-rise design (<95°C) minimizes energy waste.

4. Modular & Customizable

Tailor voltage ratings (up to 110kV), cooling methods (AN/AF), and dimensions to fit your substation layout. Options include:

- Compact models for space-constrained sites

- High-temperature editions (desert climates)

- Retrofits for aging grid infrastructure

4.Real-World Applications

Be used in a wide range of industries.

Industrial Plants

Eliminate power factor penalties in CNC machines and assembly lines while handling surge currents up to 100x rated capacity.

Substation

Stabilizes substation voltage against harmonics and intermittent generation from renewable inverters.

Commercial Buildings

Retrofit aging systems in hospitals or malls with silent (<45dB), flame-retardant capacitors that meet NFPA 70 fire codes.

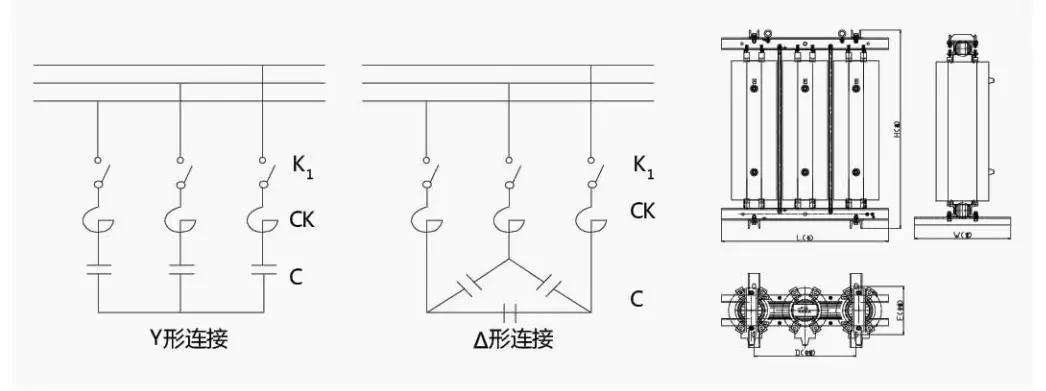

5.How It Works?

The reactor limits voltage spikes by absorbing excess reactive power from capacitive loads. Its iron core splits magnetic flux into uniform segments via air gaps, minimizing eddy current losses. The result? Smoother voltage regulation and fewer grid disturbances.

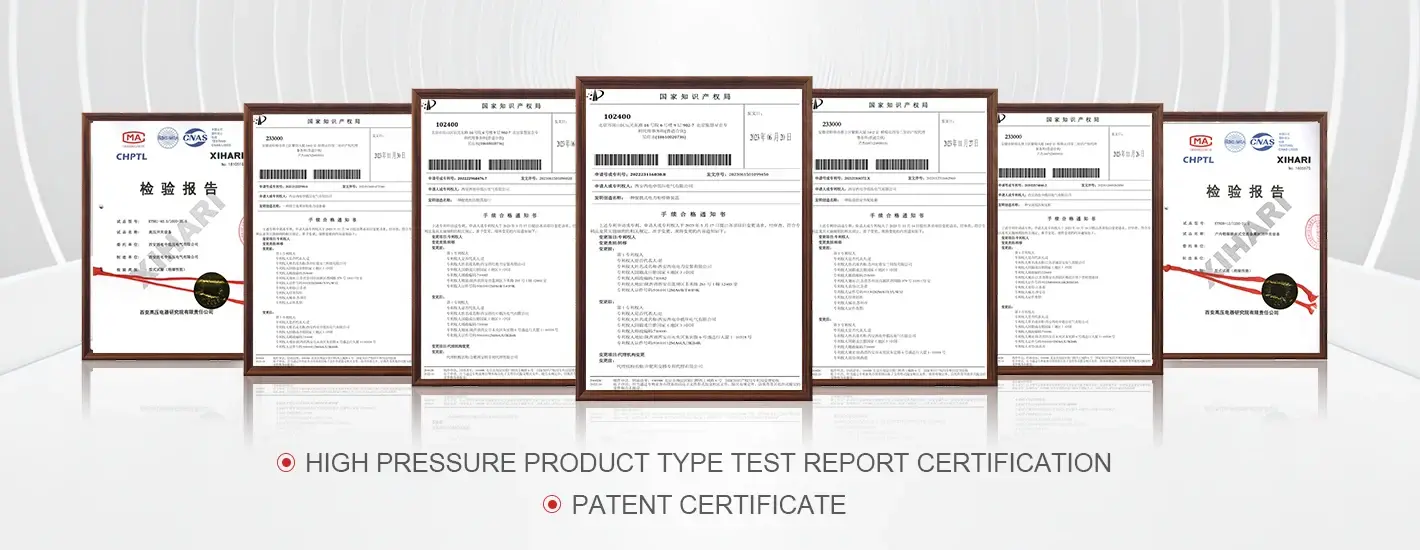

6.Manufacturing Excellence

Every BKSC Dry-type Iron Core Shunt Reactor undergoes:

- Material Testing: Only annealed silicon steel and Class F insulators are used.

- Process Control: Fully automated winding and curing (48h at 160°C).

- Quality Checks: 12-step inspection protocol, including impulse and temperature-rise tests.

7.Why Choose Us?

- 30+ Patents: Innovations in noise reduction and thermal management.

- 24/7 Support: On-site commissioning and troubleshooting.

- Proven Results: 500+ installations across 20 countries.

8.FAQs

Q: How does this reactor handle humidity?

A: The epoxy-coated coils and IP54 enclosure protect against moisture ingress.

Q: Can it operate in desert climates?

A: Yes—our high-temperature edition uses advanced cooling fins and heat-resistant adhesives.

Q: What’s the lead time for custom orders?

A: Typically 8–12 weeks, depending on design complexity.

Q: Do you provide installation guides?

A: Yes! We offer detailed manuals and video tutorials.

9.Contact Us

Email: xaxd_electric@163.com

Upgrade your grid’s reliability with the BKSC Dry-type Iron Core Shunt Reactor—where innovation meets durability.

10.Factory Show

11.Equipment Display

12.Application Cases

State Grid systems, power engineering, steel and metallurgy, petrochemicals, rail transportation, energy and water conservancy, construction, environmental protection, and renewable energy sectors

13.Team and Exhibition

Send Inquiry