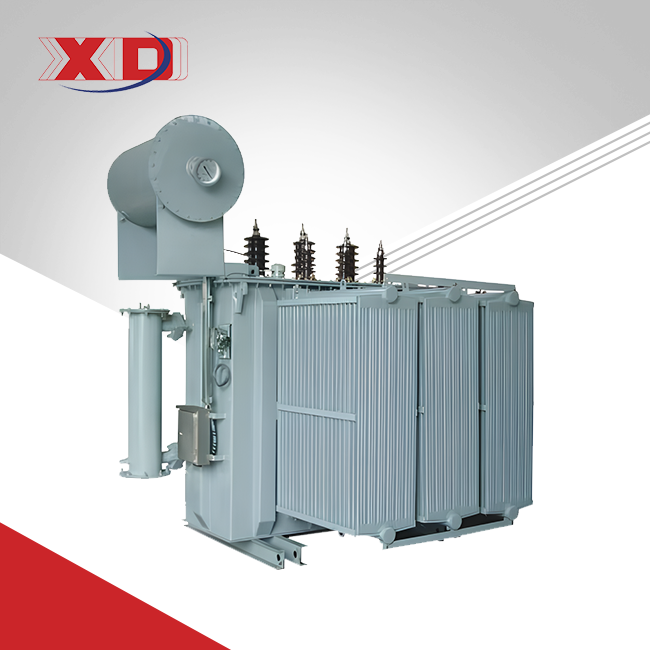

10kV Oil-immersed Distribution Transformer

2.Frequency:50/60Hz

3.Capacity:30~1600kva

4.Rated voltage:10kV

5.Winding material:copper\Aluminum

6.Taping range of HV:±5%,±2*2.5%

7.We offer choice of wound core (for efficiency) or stacked core (proven reliability).

8.You can select either standard conservator design or fully sealed, maintenance-free construction.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1.10kV Oil-Immersed Distribution Transformer: Reliable Power for Demanding Applications

When you need a robust solution for medium-voltage power distribution, the 10kV Oil-immersed Distribution Transformer stands out for its durability and adaptability. Designed to handle input voltages of 10kV and deliver stable 400V output, this transformer is engineered for industrial plants, renewable energy projects, and utility grids. With capacities ranging from 30kVA to 1600kVA, it balances performance with energy efficiency, ensuring your operations stay powered even in extreme conditions.

|

|

|

|

|

2.Technical Specifications at a Glance

- Input/Output Voltage: 10kV/400V

- Frequency: 50Hz or 60Hz

- Capacity: 30–1600kVA

- Winding Material: Copper or Aluminum

- Voltage Adjustment: ±5% or ±2×2.5% tapping

- Core Options: Wound (high efficiency) or stacked (proven reliability)

- Design: Choose between standard conservator or sealed, maintenance-free models.

-

Type Raised Capacity (kVA) HV (kV) Tapping Range of HV LV (kV) Connection symbol NO-load Loss (kW) Load Loss (kW) NO-load Current (%) Short-circuit Impedance (%) S9-30/10 30 6

6.3

10

10.5

11±5%

±2×2.5%0.4 Yyn0 0.13 0.6 2.1 4 S9-50/10 50 0.17 0.87 2 4 S9-63/10 63 0.2 1.04 1.9 4 S9-80/10 80 0.25 1.25 1.8 4 S9-100/10 100 0.29 1.5 1.6 4 S9-125/10 125 0.34 1.8 1.5 4 S9-160/10 160 0.4 2.2 1.4 4 S9-200/10 200 0.48 2.6 1.3 4 S9-250/10 250 0.56 3.05 1.2 4 S9-315/10 315 0.67 3.65 1.1 4 S9-400/10 400 0.8 4.3 1 4 S9-500/10 500 0.96 5.15 1 4 S9-630/10 630 1.2 6.2 0.9 4.5 S9-800/10 800 1.4 7.5 0.8 4.5 S9-1000/10 1000 1.7 10.3 0.7 4.5 S9-1250/10 1250 1.95 12 0.6 4.5 S9-1600/10 1600 2.4 14.5 0.6 4.5 Type Rated Capacity (kVA) Oil (kg) Total (kg) L (mm) W (mm) H (mm) Base Dimension (mm) S9-30/10 30 65 295 1200 400 1085 400×400 S9-50/10 50 85 395 930 550 1050 400×400 S9-63/10 63 100 440 945 545 1080 400×450 S9-80/10 80 110 510 960 620 1100 400×450 S9-100/10 100 115 540 1200 590 1180 400×450 S9-125/10 125 130 660 1250 670 1210 550×550 S9-160/10 160 150 740 1325 670 1295 550×550 S9-200/10 200 160 850 1325 695 1295 550×550 S9-250/10 250 200 1050 1400 695 1380 550×650 S9-315/10 315 240 1230 1490 755 1570 550×650 S9-400/10 400 250 1480 1530 950 1690 660×660 S9-500/10 500 315 1750 1590 960 1690 660×660 S9-630/10 630 375 2050 1980 1085 1710 820×820 S9-800/10 800 500 2525 2020 1045 1795 820×820 S9-1000/10 1000 530 2780 2020 1170 1840 820×820 S9-1250/10 1250 620 3400 2120 1170 2250 820×820 S9-1600/10 1600 750 4050 2420 1225 2325 820×820

3.Key Features & Advantages

1. Built to Last in Tough Environments

Our product resists humidity, dust (IP55-rated), and temperatures from -40°C to 55°C. Its corrosion-resistant tank and silica gel breathers make it ideal for coastal regions, mining sites, or offshore wind farms.

2. Energy Efficiency You Can Trust

Optimized core designs reduce no-load losses by up to 30%, aligning with EU EcoDesign standards. For renewable energy projects, models with ±0.5% voltage regulation ensure smooth grid synchronization.

3. Customization Without Compromise

Need a compact unit for urban substations? Or an ATEX-certified transformer for explosive environments? We tailor winding configurations, cooling systems, and enclosures to your needs.

4. Silent Operation

Noise levels stay below 65dB—perfect for hospitals, schools, or residential areas.

4.Where It Performs Best?

Industrial Facilities

- Withstands 150% overloads for 2 hours in mining/oil & gas operations.

- Seismic-resistant designs meet Zone 4 earthquake requirements.

Solar/Wind Farms

- Handles 125% intermittent loads from inverters.

- Low-loss (<3% at 30% load) models maximize ROI.

Utility Grids

- Amorphous core options achieve 99% efficiency for EcoDirective compliance.

- Modular designs simplify grid expansion.

5.How It Works: Simplified

The 10kV Oil-immersed Distribution Transformer uses a magnetic core to step down voltage. Insulating oil cools the windings while preventing arcing. Advanced tap changers adjust output voltage dynamically, maintaining stability during demand spikes.

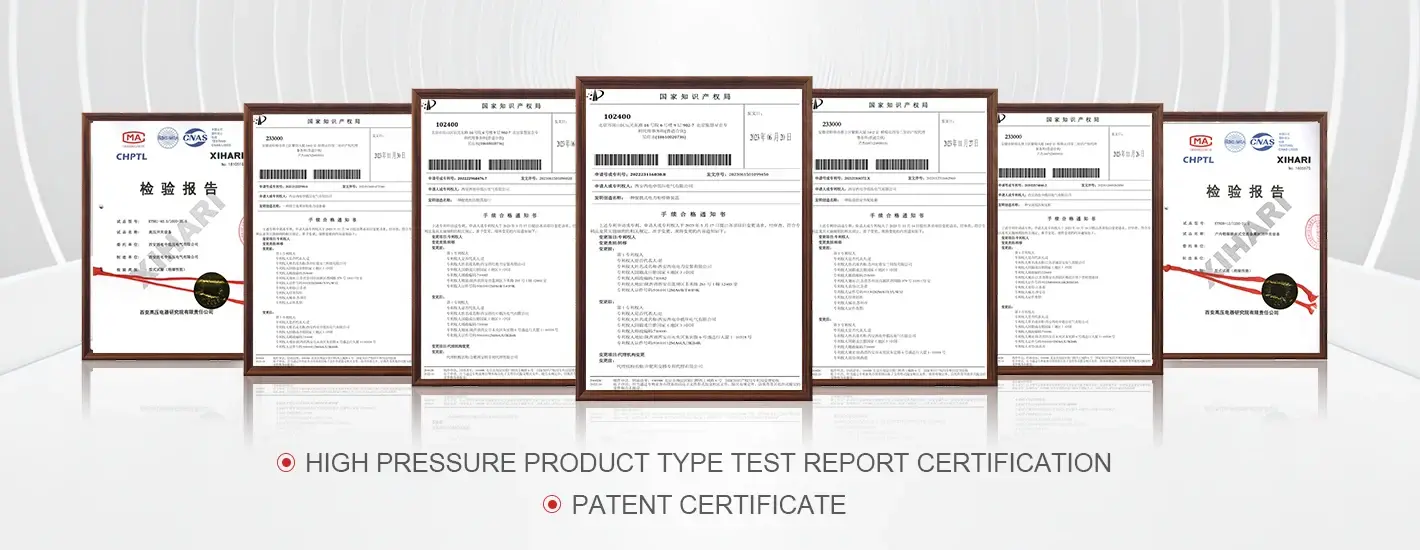

6.Quality That Meets Global Standards

Our manufacturing process includes:

- Material Testing: Grain-oriented steel cores reduce hysteresis losses.

- Leak Checks: 24-hour pressure tests on welded tanks.

- Certifications: IEC 60076, ISO 9001, CE, UL, and GOST-R.

7.Why Choose Us?

- 25+ Years of Expertise: Backed by patents in transformer design.

- End-to-End Support: 24/7 technical assistance and 10-year warranty.

- Sustainable Practices: Recyclable oil and energy-efficient production.

8.FAQs

Q: How long does delivery take?

A: Standard units ship in 8–10 weeks; expedited options available.

Q: Can it operate in -40°C winters?

A: Yes! Ask about our low-temperature oil formulation.

Q: Do you provide installation guidance?

A: We supply detailed manuals and offer on-site commissioning support.

Q: What’s the lifespan?

A: 25+ years with proper maintenance.

9.Contact Us

Got a unique requirement? Contact our engineers at xaxd_electric@163.com for a customized 10kV Oil-immersed Distribution Transformer solution.

10.Factory Show

11.Equipment Display

12.Application Cases

State Grid systems, power engineering, steel and metallurgy, petrochemicals, rail transportation, energy and water conservancy, construction, environmental protection, and renewable energy sectors

13.Team and Exhibition

Send Inquiry