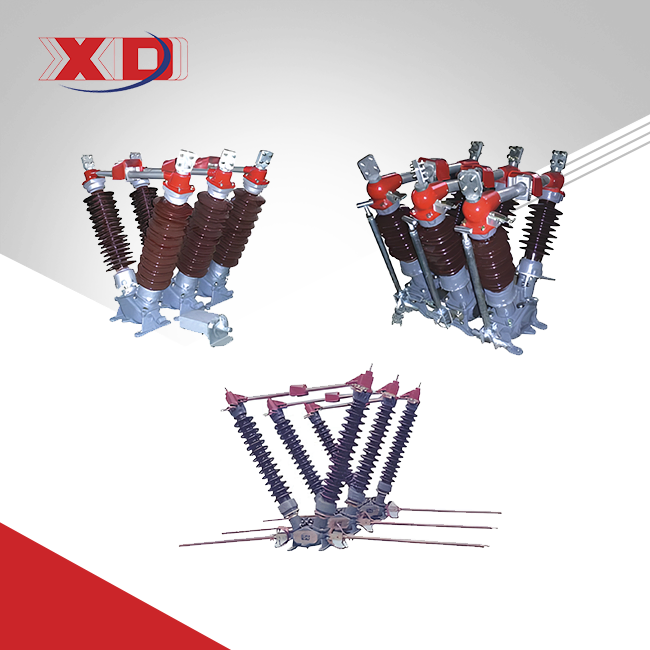

GW10 High Voltage Disconnect Switch

2.Stainless steel transmission system (pins, bushings, joints, bearings)

3.Flexible busbar connections

4.Externally compressed stainless contact springs (anti-rust, stable pressure)

5.Aluminum alloy profile

6.Enhanced heat dissipation, maintenance-free

7.Bent copper plates (easy maintenance)

8.Short friction travel during operation

9.Grading rings + shields at contacts

10.Optimized E-field distribution, reduced RF interference

11.Optional installation on both base sides

12.rated voltage:126-550kv

13.rated current:max 5000A

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

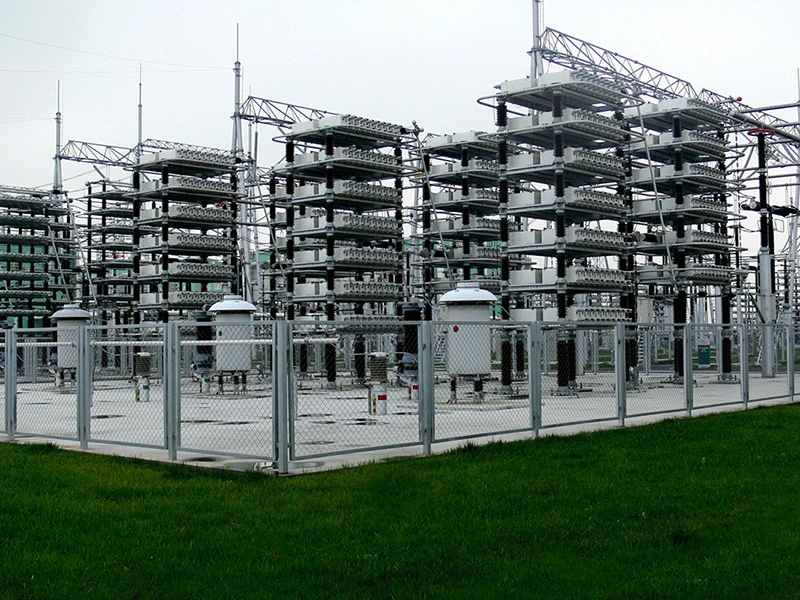

1.GW10 High Voltage Disconnect Switch: Reliable Power Grid Protection

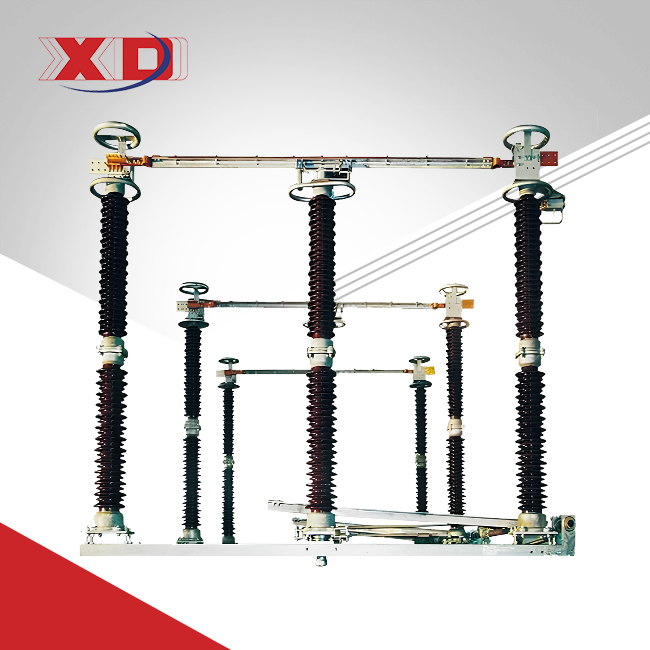

When you need a robust solution for high-voltage busbar isolation, the GW10 High Voltage Disconnect Switch stands out. Designed for 126–550 kV transmission networks, this outdoor disconnect switch ensures safe electrical isolation in substations, power plants, and industrial grids. Its single-column vertical pantograph design, corrosion-resistant materials, and compliance with IEC 62271-102 make it ideal for harsh environments—from coastal salinity to extreme temperatures.

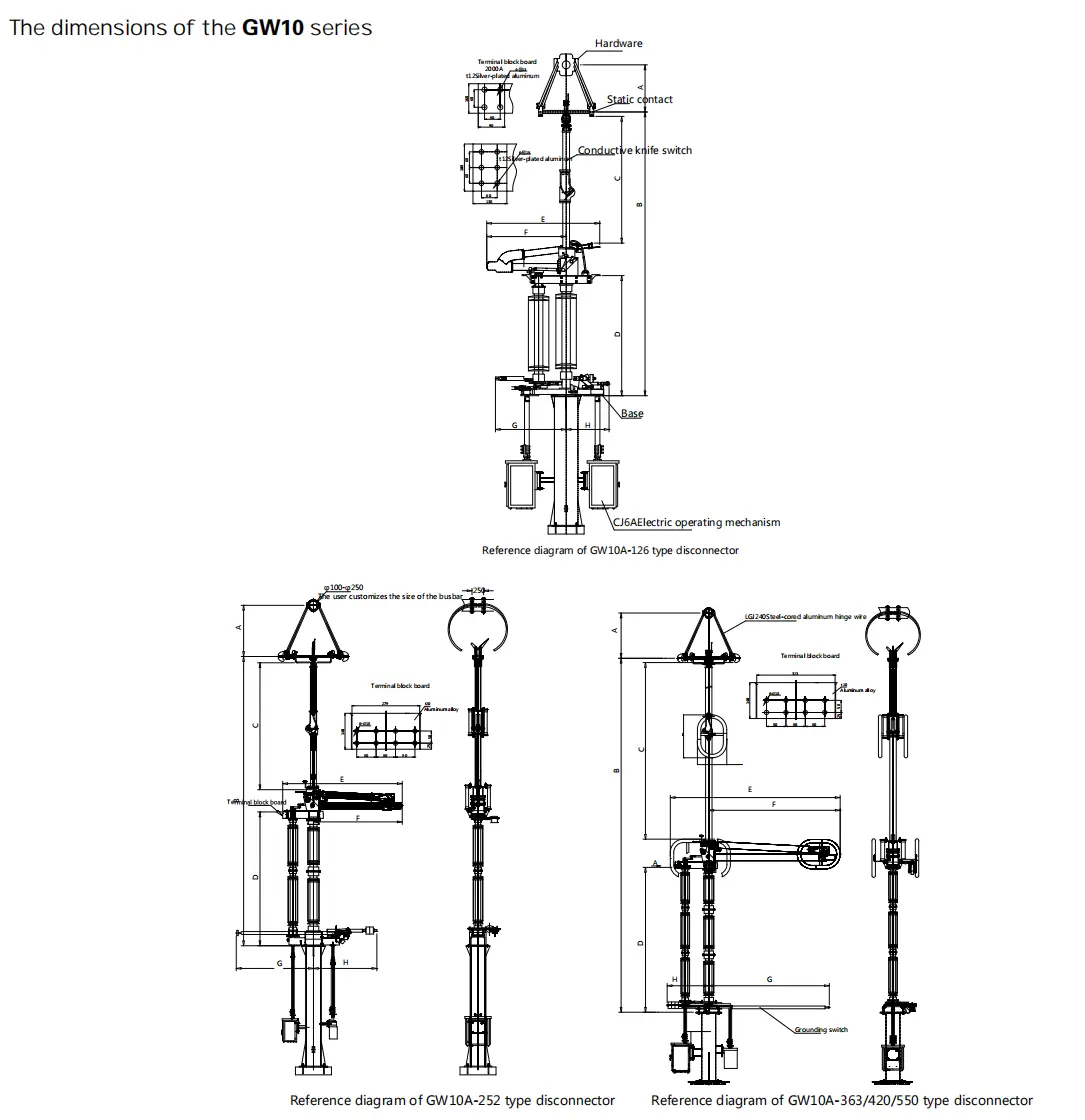

2.Technical Specifications

| Model Size | A | B | C | D | E | F | G | H | Operation Mode |

| GW10A-126 | 600~900 | 3562 | ≥1600 | 1527 | 1440 | 1100 | 950 | 600 | Three-phase motorized operation |

| GW10A-145 | 600~860 | 4162 | 1950 | 1827 | 1650 | 1155 | 1250 | 600 | |

| GW10A-252 | 600~900 | 5965 | ≥2550 | 2760 | 2465 | 1831 | 1600 | 1310 | |

| GW10A-363 | 800~1100 | 7960 | 3540 | 3665 | 3180 | 2283 | 1250 | 3385 | Phase-separated operation |

| GW10A-420 | 800~1100 | 9120 | 4100 | 4265 | 3460 | 2563 | 1250 | 4020 | |

| GW10A-550 | 800~1100 | 10520 | 5100 | 4665 | 3960 | 3063 | 1250 | 4420 |

3.Key Features & Advantages

1. Durability in Harsh Conditions

The product uses stainless steel components and hot-dip galvanized steel to resist rust, pollution, and salt fog. Its aluminum alloy profile enhances heat dissipation, ensuring stable performance even in desert or coastal areas.

2. Low Maintenance & High Efficiency

With a maintenance-free design and self-cleaning insulators, this switch reduces downtime. The short friction travel during operation minimizes wear, while bent copper plates simplify repairs.

3. Optimized Safety

Grading rings and shields at contacts ensure even electric field distribution, reducing radio frequency interference. Externally compressed stainless springs provide stable pressure for reliable disconnection.

4. Flexible Installation

Mountable on both base sides, the switch adapts to space-constrained substations or retrofits.

4.Real-World Applications

Be used in a wide range of industries.

Industrial Plants

Eliminate power factor penalties in CNC machines and assembly lines while handling surge currents up to 100x rated capacity.

Substation

Stabilizes substation voltage against harmonics and intermittent generation from renewable inverters.

Commercial Buildings

Retrofit aging systems in hospitals or malls with silent (<45dB), flame-retardant capacitors that meet NFPA 70 fire codes.

5.How It Works?

The GW10 High Voltage Disconnect Switch operates via a vertical pantograph mechanism. When activated, the stainless steel arms lift the contacts vertically, breaking the circuit without arcing. This design ensures smooth operation even after 10,000+ cycles.

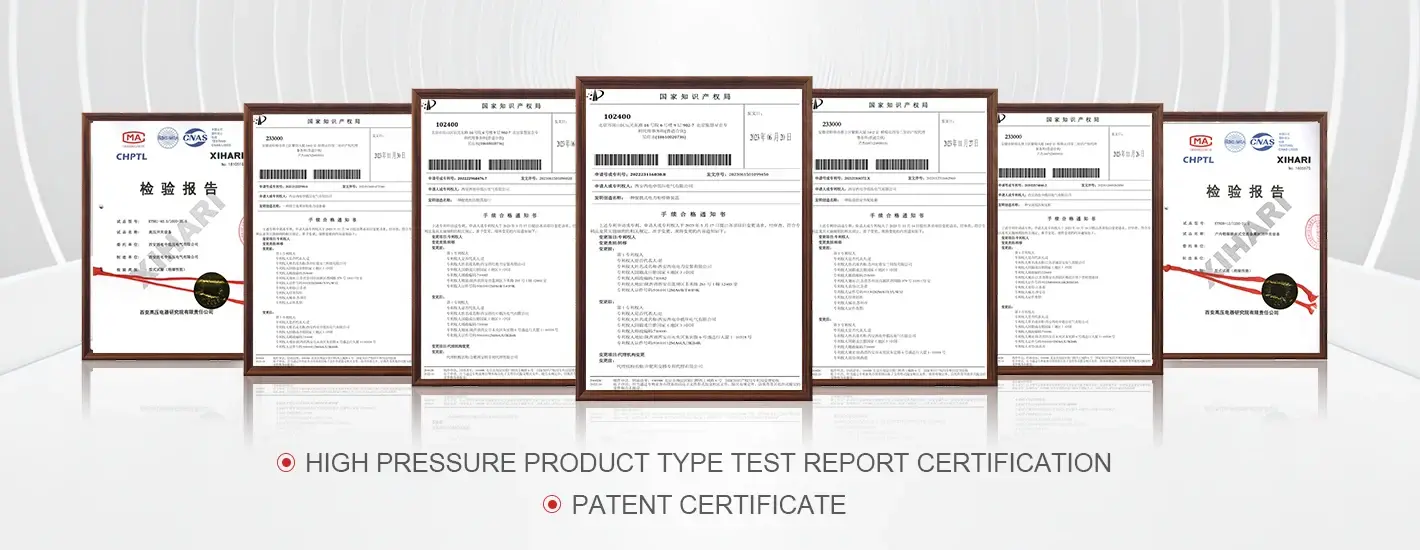

6.Manufacturing & Quality Assurance

- ISO 9001-Certified Production: Every switch undergoes 23+ quality checks, from raw materials to final assembly.

- Rigorous Testing: Dielectric strength tests (up to 550 kV), seismic simulations (IEEE 693), and salt fog corrosion tests.

- Patented Innovations: 12+ patents in insulator materials and contact spring technology.

7.Why Choose Us?

1. Expertise: 20+ years in high-voltage solutions, backed by R&D partnerships with national labs.

2. Customization: Modify switch configurations for voltage-specific needs (e.g., 550 kV+).

3. Sustainability: Energy-efficient manufacturing aligned with ISO 14001.

8.FAQs

1. Can the GW10 handle coastal salinity?

Yes! Stainless steel components and hot-dip galvanized steel pass 1000-hour salt fog tests.

2. What’s the lead time for 500+ units?

We offer JIT delivery—contact us for project-specific timelines.

3. Is onsite installation support available?

Absolutely. Our engineers provide step-by-step guidance to minimize assembly errors.

4. How does the switch integrate with smart grids?

Optional IoT sensors enable real-time monitoring of contact wear and insulation status.

9.Contact Us

Need a GW10 High Voltage Disconnect Switch tailored to your grid? Email our team at xaxd_electric@163.com for quotes, certifications, or technical details.

10.Factory Show

11.Equipment Display

12.Application Cases

State Grid systems, power engineering, steel and metallurgy, petrochemicals, rail transportation, energy and water conservancy, construction, environmental protection, and renewable energy sectors

13.Team and Exhibition

Send Inquiry