GW11 High Voltage Disconnect Switch

2.Simple, easy-install flexible joints.

3.Low-force, reliable self-lubricating bushings; durable stainless/copper levers/shafts.

4.Enclosed transmission minimizes environmental impact.

5.Hot-dip galvanized base extends life, improves appearance.

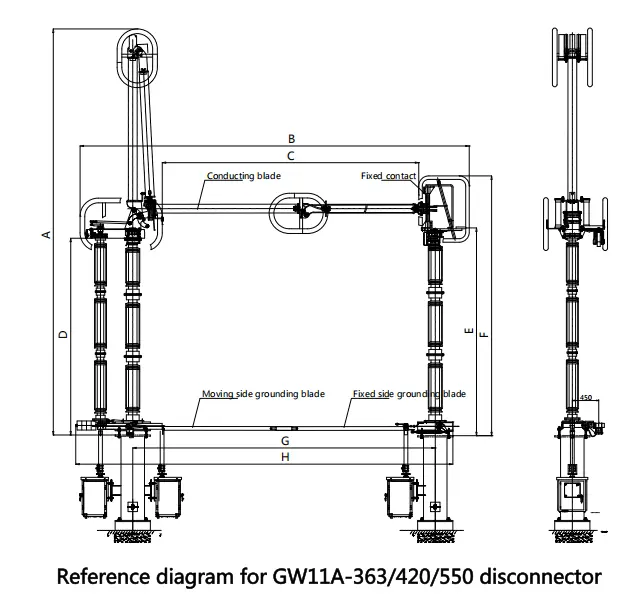

6.Modular shared-contact design (252-420kV) saves ~30% space, reduces cost, enables combinations.

7.rated voltage:126-800kv

8.rated current:max 5000A

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1.GW11 High Voltage Disconnect Switch: Reliable Power Grid Protection

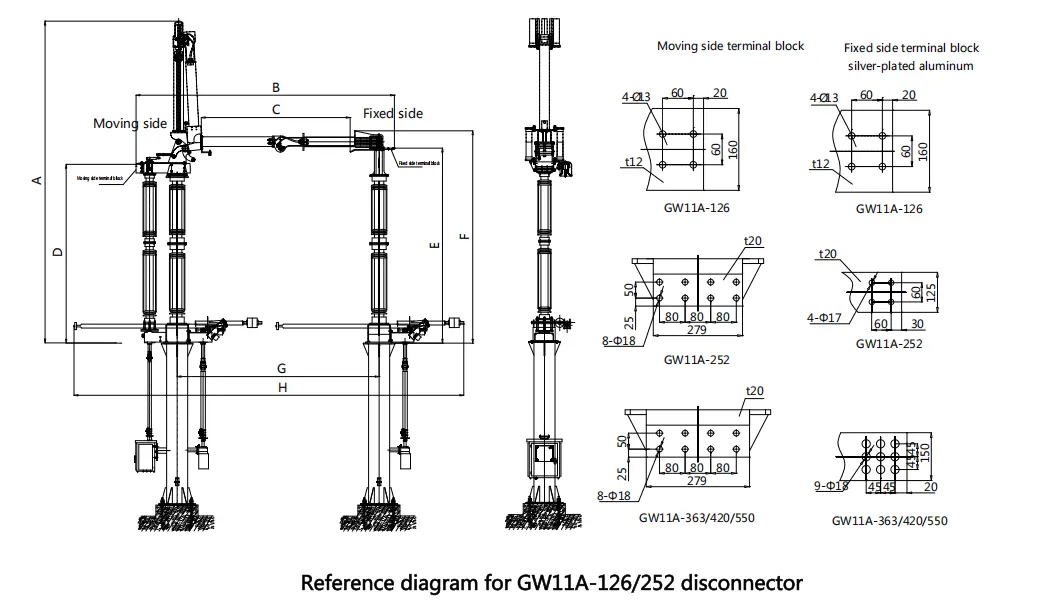

When managing high-voltage power systems, the GW11 High Voltage Disconnect Switch stands out as a critical component for safe electrical isolation and grid reliability. Designed for outdoor use in demanding environments, this double-column horizontal pantograph disconnector ensures seamless switching of circuits up to 800 kV. Its robust construction and smart design minimize downtime while meeting global certifications like IEC 62271 and IEEE C37.32.

2.Technical Specifications

- Rated Voltage: 126 kV to 800 kV

- Rated Current: Up to 5000 A

- Design: Horizontal pantograph with enclosed transmission

- Material: Corrosion-resistant aluminum alloy conductors, stainless steel/copper levers

- Lifespan: 30+ years with ≤10,000 maintenance-free operations

- Certifications: IEC, IEEE, GB/T 1985, CE, RoHS

-

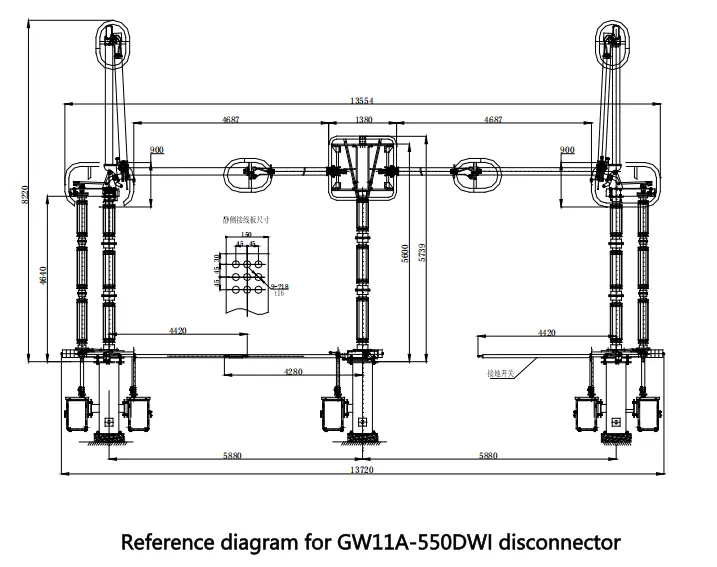

Model Size A B C D E F G H Operation Mode GW11A-126 2712 2710 ≥1470 1527 1552 1685 1920 3100 Three-phase mechanism operation GW11A-252 4967 4000 2300 2760 3010 3150 3125 6035 GW11A-363 6392 5676 3416 3640 3784 4666 4200 5500 GW11A-420 7320 6236 3976 4240 4384 5266 4760 6100 Phase-separated operation GW11A-550 8200 7020 4760 4640 4784 5666 5544 6900 GW11A-550L 8200 13554 4687 4640 5600 5739 2×5880 13720 GW11A-800 12905 11035 6435 7870 8032 9180 8000 10000

3.Key Features & Benefits

1. Enhanced Durability & Performance

- Lightweight & Strong: Aluminum alloy conductors reduce weight by 40% compared to traditional materials while resisting corrosion.

- Low-Maintenance Operation: Sealed motion mechanisms and self-lubricating bushings cut servicing needs by 60%.

- Space-Saving Design: Modular shared-contact layouts save 30% space in 252–420 kV installations.

2. Smart Grid Compatibility

- Hot-dip galvanized bases withstand extreme temperatures (-40°C to +85°C) and humidity.

- Optional IoT sensors enable real-time monitoring for predictive maintenance.

3. Safety First

- Mechanical/electrical interlocks prevent unsafe operations between main and earthing blades.

- Horizontal insulation breaks ensure safe live-line maintenance.

4.Where It's Used?

Be used in a wide range of industries.

Industrial Plants

Eliminate power factor penalties in CNC machines and assembly lines while handling surge currents up to 100x rated capacity.

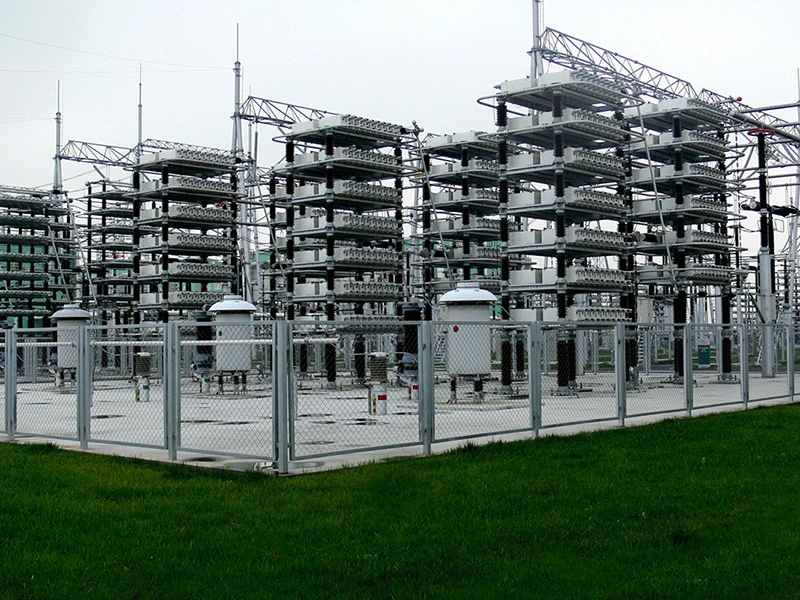

Substation

Stabilizes substation voltage against harmonics and intermittent generation from renewable inverters.

Commercial Buildings

Retrofit aging systems in hospitals or malls with silent (<45dB), flame-retardant capacitors that meet NFPA 70 fire codes.

5.How It Works?

This outdoor disconnector uses a pantograph mechanism to physically separate circuits. When activated, its dual blades create a visible air gap, ensuring electrical isolation. The enclosed transmission system prevents dust/sand ingress, while flexible joints allow easy installation on uneven terrain.

6.Built to Last: Manufacturing Excellence

Our production process includes:

- ISO-Certified Quality Control: Raw material checks, precision machining, and 72-hour load testing.

- Eco-Friendly Practices: Lead-free materials and energy-efficient manufacturing.

- Customization: Adjust blade configurations or add earthing switches for regional grid requirements.

7.Why Choose Us?

- 30+ Years in High-Voltage Solutions

- 1,200+ Successful GW11 Installations Worldwide

- 24/7 Technical Support & 5-Year Warranty

- Certifications: ISO 9001, ISO 14001, CE, RoHS

8.Frequently Asked Questions

Q: Can this switch handle coastal environments?

A: Yes! Stainless steel components and hot-dip galvanized bases resist saltwater corrosion.

Q: How does the pantograph design improve reliability?

A: Dual-column horizontal blades distribute mechanical stress evenly, reducing wear.

Q: What’s the installation time?

A: Pre-assembled modules cut installation to 4–6 hours vs. 12+ hours for traditional switches.

9.Contact Us

Email our team at xaxd_electric@163.com for datasheets, pricing, or custom requests.

Optimize your grid’s safety and efficiency with the GW11 High Voltage Disconnect Switch – where innovation meets reliability.

10.Factory Show

11.Equipment Display

12.Application Cases

State Grid systems, power engineering, steel and metallurgy, petrochemicals, rail transportation, energy and water conservancy, construction, environmental protection, and renewable energy sectors

13.Team and Exhibition

Send Inquiry