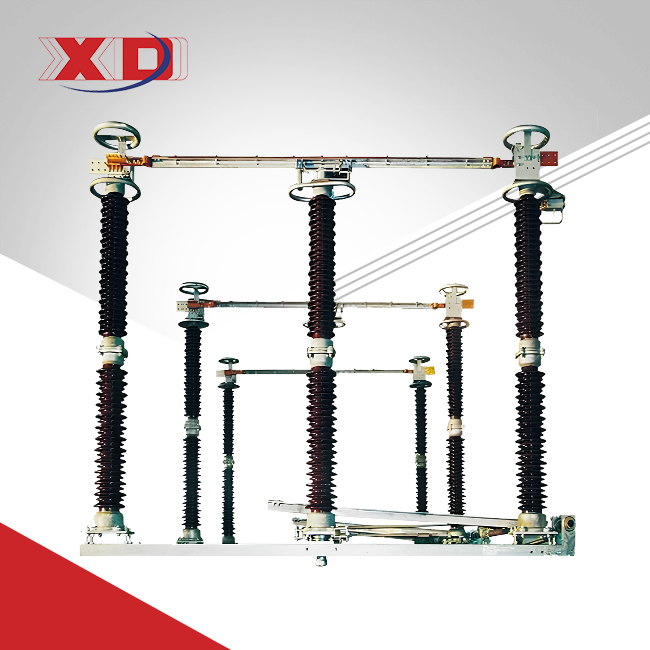

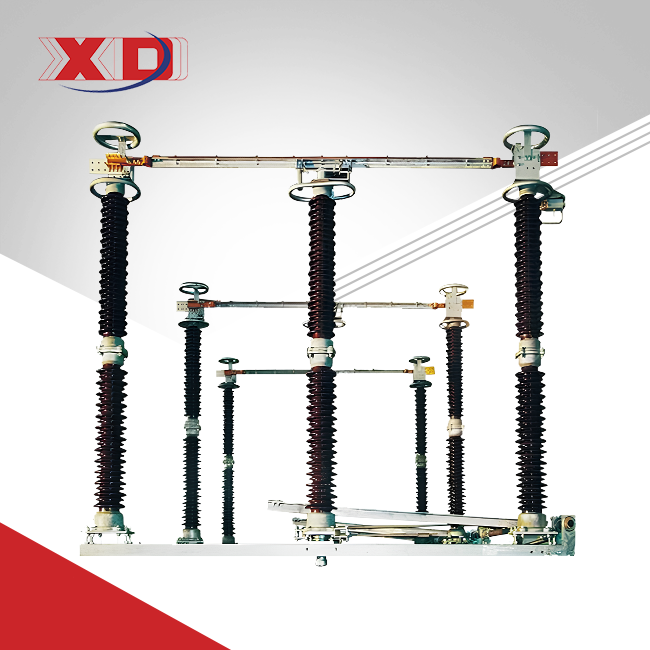

GW7 High Voltage Disconnect Switch

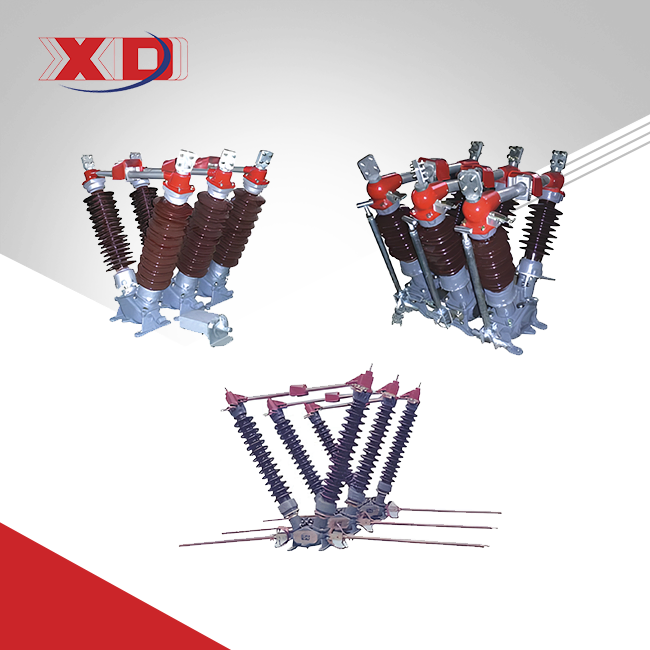

2.Stationary contacts: Fixed w/ external springs (no shunting), operation limiters

3.Contacts: High pressure, self-cleaning, ice-breaking

4.Conductive rods: Monobloc Al alloy (high current/heat dissipation/corrosion resistant)

5.Base: Hot-dip galvanized steel, integral design (anti-settlement, easy install)

6.Drive: Corrosion-proof components (stainless/composite bearings)

7.Earth switch: Counterweight balanced (low force)

8.Contacts: Silver-inlaid Cu (high strength/current, anti-corrosion)

9.rated voltage:max252-1100kv

10.rated current:max6300A

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

1.GW7 High Voltage Disconnect Switch: Reliable Power Grid Protection

When you need uncompromising safety and durability for high-voltage transmission systems, the GW7 High Voltage Disconnect Switch delivers. Designed for outdoor installations in demanding environments, this switch ensures secure isolation of electrical equipment in power grids up to 1100kV. Its horizontal rotating mechanism and corrosion-resistant construction make it a top choice for utility companies prioritizing reliability, compliance, and reduced lifecycle costs.

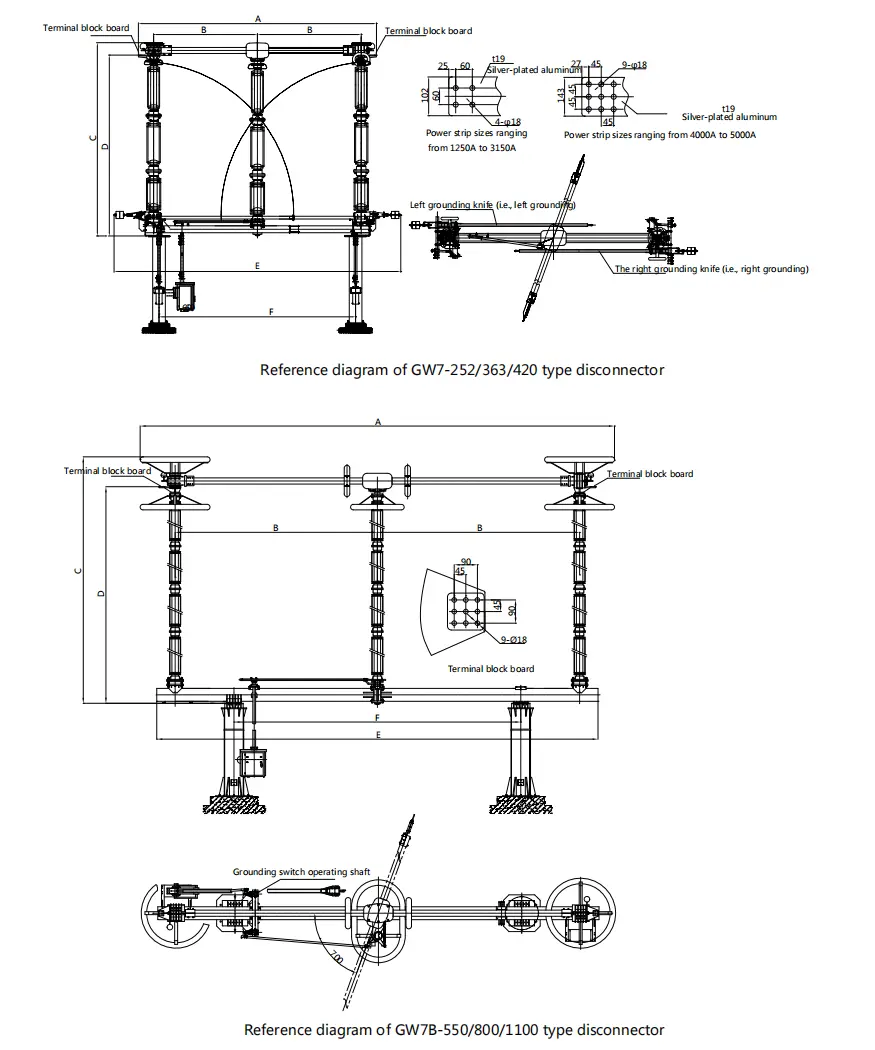

2.Technical Specifications at a Glance

| Model Size | A | B | C | D | E | F | Operation Mode |

| GW7B-252 | 4004 | 1670 | 3180 | 2930 | 5075 | 3125 | Three-phase mechanical linkage |

| GW7B-363 | 5162 | 2250 | 4240 | 3970 | 6500 | 4270 | Phase-separated operation |

| GW7B-420 | 5714 | 2600 | 4840 | 4570 | 7770 | 4970 | Phase-separated operation |

| GW7B-550 | 7480 | 3200 | 5811 | 5252 | 7400 | 4000 | Phase-separated operation |

| GW7B-800 | 11600 | 5000 | 7951 | 7218 | 11000 | 6800 | Phase-separated operation |

| GW7B-1100 | 12900 | 5500 | 10051 | 9318 | 12000 | 7800 | Phase-separated operation |

3.6 Reasons to Trust the GW7 Series

1. Built for Extreme Conditions

The GW7 outdoor electrical disconnect switch withstands temperature fluctuations (-40°C to +55°C), ice, and coastal corrosion. Its self-cleaning contacts and ice-breaking design ensure uninterrupted operation during storms.

2. Low Maintenance, High Efficiency

Precision-engineered stainless steel bearings and a counterweight-balanced earth switch reduce operational force by 40%, cutting maintenance costs.

3. Smart Grid Ready

Optional IoT-enabled monitoring integrates with SCADA systems for real-time status updates—ideal for modernizing legacy power networks.

4. Safety First

Silver-inlaid copper contacts prevent arcing, while mechanical interlocks block accidental activation during maintenance.

5. Rapid Installation

A modular design and pre-assembled components cut installation time by 30% compared to traditional switches.

6. Global Certifications

Demanded certifications ensure compliance across all kinds of markets.

4.Where the GW7 Excels?

Be used in a wide range of industries.

Industrial Plants

Eliminate power factor penalties in CNC machines and assembly lines while handling surge currents up to 100x rated capacity.

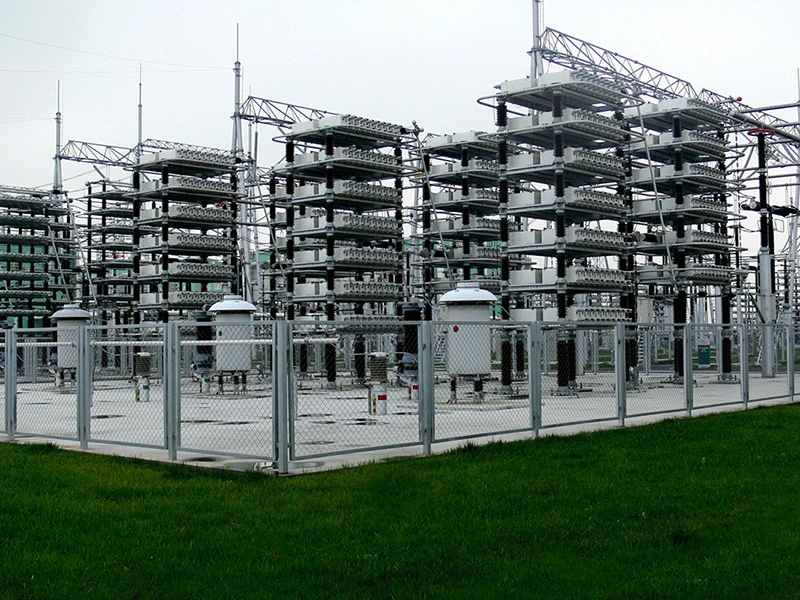

Substation

Stabilizes substation voltage against harmonics and intermittent generation from renewable inverters.

Commercial Buildings

Retrofit aging systems in hospitals or malls with silent (<45dB), flame-retardant capacitors that meet NFPA 70 fire codes.

5.Engineered for Long-Term Performance

Robust Construction

The 363kV disconnect switch GW7 High Voltage Disconnect Switch features a flip-type blade system for smooth operation under high pressure. External springs on stationary contacts eliminate shunt current risks, while hot-dip galvanized steel bases prevent ground settlement.

Quality Assurance

Every GW7 unit undergoes:

- 72-hour salt spray testing

- 10,000 mechanical operation cycles

- Thermal imaging to verify heat dissipation

6.Why Partner With Us?

ISO 9001/14001 Certified Manufacturing

Our fully automated production line ensures consistency across bulk orders (100–500 units/year).

End-to-End Support

From seismic-resistant configurations for California grids to sand-proof variants for Saudi Arabia, we tailor solutions to your region.

Proven Track Record

Trusted by State Grid Corporation of China and 120+ utilities worldwide since 2008.

24/7 Technical Assistance

Get on-site troubleshooting within 72 hours—anywhere.

7.FAQs

Q: How often should we inspect the GW7 switch?

A: Annual visual checks and lubrication every 5 years are sufficient under normal conditions.

Q: Can it handle short-circuit currents?

A: Yes—it withstands 50kA RMS for 3 seconds as per IEC 62271-102.

Q: What’s the lead time ?

A: Our general lead time is 4-6 weeks after confirmation of drawings.

8.Contact Us

Email our engineering team today at xaxd_electric@163.com for:

- Customized quotations

- Certification packages

- Technical drawings

Serving utilities and EPC contractors in 15 countries—GW7 High Voltage Disconnect Switch, let’s build a safer power grid together.

9.Factory Show

10.Equipment Display

11.Application Cases

State Grid systems, power engineering, steel and metallurgy, petrochemicals, rail transportation, energy and water conservancy, construction, environmental protection, and renewable energy sectors

12.Team and Exhibition

Send Inquiry